CNC machining achieves precise part geometry by combining advanced computer programming with careful material selection and tool calibration. You control the process to guarantee tight tolerances and intricate shapes, adjusting cutting parameters based on material properties. Proper calibration minimizes errors and enhances surface quality, while selecting the right materials ensures durability and performance. Paying attention to these factors helps produce consistent, high-quality parts—if you want to discover more, keep exploring how these elements work together.

Key Takeaways

- CNC machining achieves precise part geometry through computer-controlled tool paths and accurate calibration.

- Material properties influence cutting parameters, directly affecting the accuracy of complex geometries.

- Proper tool calibration ensures dimensional accuracy and surface finish in intricate CNC-produced parts.

- Understanding vibrational and machinability factors helps optimize tool movements for precise geometries.

- Combining material selection with meticulous calibration guarantees consistent, high-precision manufacturing outcomes.

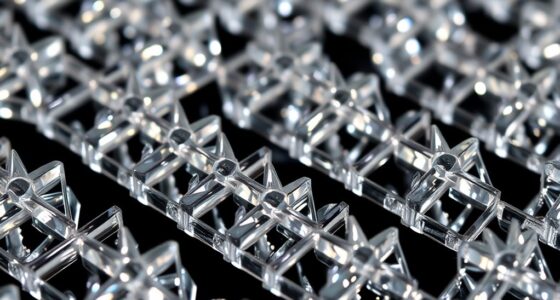

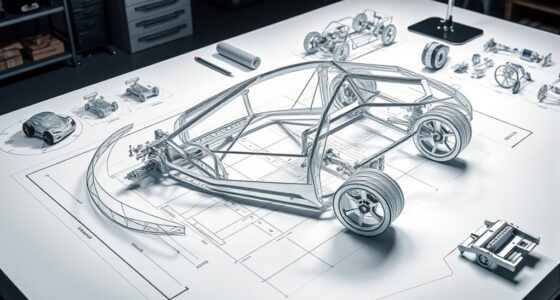

CNC machining has revolutionized manufacturing by allowing precise, automated control over complex part production. It’s a process that combines computer programming with high-precision machinery to craft parts with tight tolerances and intricate geometries. When you’re working with CNC, your success hinges heavily on critical factors like material selection and tool calibration, which directly influence the quality and accuracy of your finished product. Selecting the appropriate material also involves understanding its vibrational properties, which can affect how it responds during the machining process and influence the surface finish. Choosing the right material is essential because it determines how well your part will perform in its intended environment. You need to contemplate properties such as strength, durability, machinability, and resistance to wear or corrosion. For example, softer materials like plastics are easier to machine and require less aggressive tool settings, while harder metals like titanium or stainless steel necessitate more robust tools and precise control. Your material choice impacts cutting speed, feed rate, and tool wear, so you must select a material that balances your project’s performance requirements with machining feasibility. Proper material selection also helps prevent issues like warping, cracking, or surface imperfections, ensuring your parts meet specifications consistently.

Equally important is tool calibration, which ensures your cutting tools are set up accurately before starting the machining process. Proper calibration involves verifying tool length, diameter, and alignment, allowing your CNC machine to execute commands with pinpoint accuracy. When tools are correctly calibrated, you minimize errors such as dimensional inaccuracies or surface roughness, which can compromise the part’s functionality. It’s critical to perform routine calibration checks, especially when switching tools or after prolonged use, to maintain consistent precision. Precise calibration also optimizes cutting parameters, reducing tool wear and prolonging the lifespan of your tools, which saves you time and costs in the long run.

Both material selection and tool calibration work hand in hand to achieve ideal results in CNC machining. If you pick a material that’s too hard or difficult to machine without adjusting your tools properly, you risk damaging your tools or producing subpar parts. Conversely, even with the perfect material, improper calibration can lead to inaccuracies, surface defects, or dimensional deviations. You need to approach each project with meticulous attention to these details, ensuring your CNC machine operates at peak performance.

In essence, mastering material selection and tool calibration empowers you to harness the full potential of CNC machining. It’s about understanding the interplay between the material’s properties and the machine’s capabilities to produce parts that meet exact specifications. When you get these factors right, you’re not just making parts—you’re creating precise, reliable components that stand up to demanding applications.

Frequently Asked Questions

How Does CNC Machining Compare to Traditional Manual Machining?

You’ll find CNC machining offers greater precision and consistency than traditional manual methods. With automation integration, your workflow becomes faster and more efficient, reducing errors. Plus, software customization allows you to tweak designs easily, ensuring complex parts are produced accurately. Unlike manual machining, CNC machines operate automatically, freeing you up for other tasks and enhancing overall productivity. This makes CNC machining a smarter choice for high-quality, repeatable parts.

What Materials Are Best Suited for CNC Machining Processes?

You’ll find that materials like aluminum, brass, and plastics are most compatible with CNC machining, thanks to their favorable material properties and ease of tool compatibility. These materials cut smoothly and produce high-quality finishes, making your process more efficient. Harder materials like titanium and stainless steel can work too, but they demand specialized tools and settings. Choosing the right material guarantees precision, reduces tool wear, and helps you achieve the best possible results.

How Do Design Tolerances Affect CNC Machining Accuracy?

Design tolerances directly impact CNC machining accuracy by defining acceptable dimensional variations. When you set tight tolerances, you require precise tolerance control, which ensures your parts meet strict specifications. Conversely, looser tolerances allow for more dimensional accuracy variation, making manufacturing easier and faster. Understanding how tolerances influence your design helps you balance quality and efficiency, ensuring your final parts align with your functional and aesthetic requirements.

What Are Common Issues Encountered During CNC Machining?

You might encounter issues like tool wear, which affects cutting precision, or fixture stability problems, causing misalignment. Excessive tool wear leads to inconsistent finishes and dimensional inaccuracies, while unstable fixtures result in vibrations and part defects. Regularly monitor tool condition and guarantee fixtures are secure to maintain accuracy. Addressing these common issues helps you achieve high-quality, precise machined parts efficiently and reliably.

How Can I Optimize CNC Program Efficiency for Complex Parts?

A stitch in time saves nine, so start by enhancing your toolpaths for complex parts. Focus on toolpath optimization to reduce unnecessary movements and cut cycles. Implement effective feed rate strategies to balance speed and precision, preventing tool wear or tool breakage. Streamlining your CNC program with these tactics improves efficiency, reduces machining time, and enhances part quality. Always test and refine your program for optimal results.

Conclusion

CNC machining revolutionizes manufacturing with its unmatched precision, ensuring your parts meet exact specifications every time. Did you know that over 80% of aerospace components are now produced using CNC technology? This highlights how essential it is for quality and safety. Embrace CNC machining to elevate your projects, reduce waste, and stay ahead in a competitive market. With such capabilities, you’re not just cutting metal—you’re shaping the future of manufacturing.