In CAD, geometry is the core that drives the creation of detailed and accurate digital models. It helps you design complex shapes, whether through mesh modeling for organic forms or parametric design for precise, adaptable structures. By understanding geometry, you can visualize, refine, and optimize your projects efficiently. Mastering these principles unshackles endless possibilities, and if you keep exploring, you’ll discover how to harness geometry’s full power for your designs.

Key Takeaways

- Geometry provides the foundational framework for creating accurate, detailed digital models in CAD software.

- Mesh modeling uses vertices, edges, and faces to construct complex, organic shapes for realistic designs.

- Parametric design enables models to automatically update when adjustable parameters or constraints are changed.

- Combining mesh and parametric techniques offers flexibility, precision, and detailed control over complex projects.

- Mastering geometric principles enhances visualization, accuracy, and efficiency in the CAD design process.

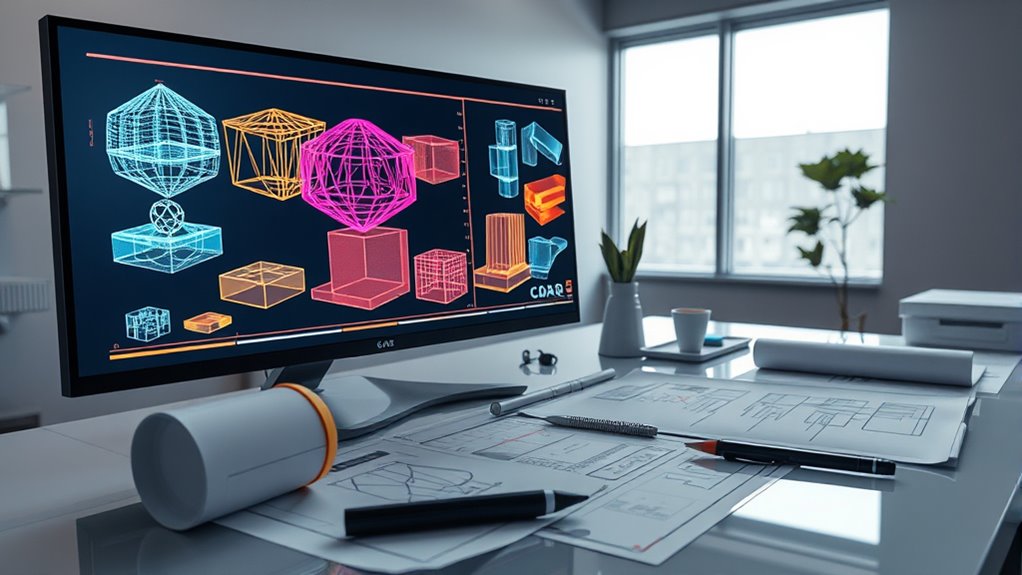

Have you ever wondered how engineers and designers create detailed plans for buildings, products, or machinery? The answer lies in the powerful world of computer-aided design, or CAD. At its core, CAD relies heavily on geometry to bring ideas to life. Whether you’re designing a sleek smartphone case or planning a complex bridge, understanding how geometry fuels CAD tools is essential. Two fundamental concepts in this realm are mesh modeling and parametric design, which work together to give you the flexibility and precision needed for modern design.

Discover how geometry drives CAD, mesh modeling, and parametric design for innovative, precise creations.

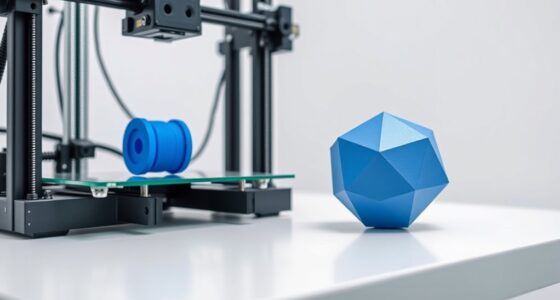

Mesh modeling is a technique that allows you to create and manipulate complex 3D shapes by working with a network of vertices, edges, and faces. Imagine it as building a sculpture out of tiny interconnected polygons. This method is especially useful for creating organic forms, detailed surfaces, or models that require intricate textures. When you use mesh modeling, you can easily refine your design by adjusting the vertices or smoothing surfaces, which gives you a high level of control over the final appearance. It’s a straightforward way to visualize and tweak your project in real-time, making it invaluable in fields like animation, game design, and product development.

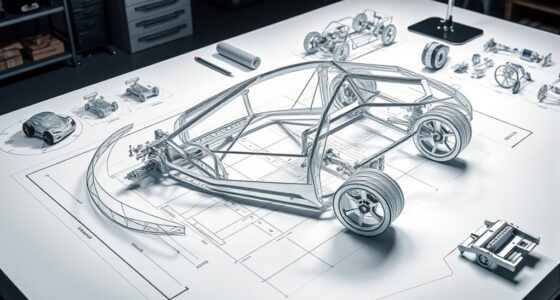

On the other hand, parametric design introduces a different approach. Instead of manually adjusting each part of your model, you define relationships and constraints using parameters. Think of it as setting rules for your design, such as dimensions, angles, or patterns, which can then be automatically updated whenever you change a parameter. This method makes your design highly adaptable, saving you time and effort when modifications are needed. For example, if you’re designing a chair and decide to change the height, all related dimensions and components can automatically update based on your predefined rules. This dynamic approach is essential in engineering and architecture because it guarantees consistency, accuracy, and efficiency.

Combining mesh modeling with parametric design provides a robust toolkit for creating complex, adaptable models. Mesh modeling gives you the ability to craft detailed, organic shapes, while parametric design ensures those shapes are based on precise, adjustable parameters. Together, they enable you to experiment, iterate, and perfect your designs with greater confidence. As you learn more about how geometry powers CAD, you’ll see how these techniques open endless possibilities, from simple prototypes to intricate architectural structures. Whether you’re a beginner or an experienced designer, mastering these concepts will help you bring your ideas to life with clarity, speed, and precision. Understanding the role of geometry in CAD is fundamental to mastering modern design tools.]

Frequently Asked Questions

How Does 3D Modeling Enhance CAD Accuracy?

3D modeling enhances CAD accuracy by using parametric constraints, which allow you to define relationships and dimensions precisely. You can manipulate these constraints to keep your design consistent, reducing errors. Additionally, geometric algorithms optimize the creation and adjustment of complex shapes, ensuring precision. This combination helps you produce detailed, accurate models efficiently, minimizing manual adjustments and improving overall design quality.

What Are Common Challenges in Applying Geometry to CAD?

You might face challenges applying geometry in CAD, especially with complex shapes requiring precise geometric constraints. Ensuring topology optimization aligns with design intent can be tricky, as it demands balancing material distribution and structural integrity. You also need to manage conflicting constraints, which can limit flexibility. Staying attentive to these issues helps you create accurate, efficient designs, but it requires careful planning and understanding of geometric principles.

How Does CAD Software Handle Complex Geometric Calculations?

You’ll find that CAD software handles complex geometric calculations through advanced geometric algorithms and parametric constraints. These tools automatically adjust designs based on set parameters, ensuring precision and flexibility. When you modify one element, the software recalculates related geometries, maintaining design integrity. This combination allows you to efficiently create intricate, accurate models while minimizing manual calculations, streamlining your design process and reducing errors.

Can CAD Geometry Be Automatically Optimized for Manufacturing?

Yes, CAD geometry can be automatically optimized for manufacturing through automated geometry tools. These features analyze your designs, suggest modifications, and streamline shapes for easier production. You can rely on the software to improve efficiency, reduce material use, and enhance part functionality. By leveraging automated geometry and manufacturing optimization, you guarantee your designs are production-ready, saving time and costs while maintaining precision and quality throughout the manufacturing process.

What Future Trends Will Influence Geometry in CAD Development?

Think of CAD geometry like a shaping clay—it’s constantly evolving. You’ll see future trends like parametric design enabling more flexible, adaptive models, and generative algorithms pushing creativity with automated variations. These advancements will make designing faster and more innovative, allowing you to explore complex forms effortlessly. As technology progresses, you’ll find your projects becoming smarter, more efficient, and increasingly aligned with manufacturing needs, transforming the way you create.

Conclusion

Now that you see how geometry fuels CAD, it’s like the backbone of every design you create. Without it, your ideas would drift aimlessly, lost in a sea of chaos. By understanding these principles, you hold the key to turning your sketches into precise, stunning models. Remember, geometry isn’t just math—it’s the magic wand that transforms your imagination into reality. Embrace it, and watch your designs soar to new heights.