If you’re exploring the best resin wash and cure stations for school makerspaces in 2026, I recommend looking at versatile, high-capacity units like the ELEGOO Mercury X and the ANYCUBIC Wash & Cure Max 3.0. These models feature efficient cleaning, uniform curing, safety covers, and user-friendly interfaces suitable for educational environments. To find the perfect fit for your needs, I’ll guide you through key features and considerations that matter most for schools.

Key Takeaways

- Prioritize stations with large capacity, supporting multiple or sizeable resin models for high-volume educational use.

- Ensure stations feature safety certifications, UV protection, and enclosed designs suitable for school environments.

- Look for user-friendly interfaces, automated functions, and adjustable curing/washing settings to streamline classroom workflows.

- Select models with compatibility across popular resin printers and resins to integrate seamlessly into existing makerspace setups.

- Consider durability, ease of maintenance, and cost-effectiveness to ensure long-term, safe, and efficient educational post-processing.

| ELEGOO Mercury X Wash & Cure Station Set |  | Best Overall | Capacity: Not specified (small/medium size) | Compatibility: ELEGOO resin printers (Mars, Saturn) | Curing Power: 14 LED lights per bar, 405nm UV | VIEW LATEST PRICE | See Our Full Breakdown |

| ANYCUBIC Wash & Cure Max 3.0 15.1L 3D Printer Station |  | Largest Capacity | Capacity: 15.1L (large chamber) | Compatibility: Most resin printers up to 13.6 inches | Curing Power: 25,000 μW/cm² UV energy | VIEW LATEST PRICE | See Our Full Breakdown |

| ELEGOO Mercury X Resin 3D Printer Wash & Cure |  | Complete System | Capacity: 7.5L (large capacity) | Compatibility: ELEGOO Saturn, Mars MSLA | Curing Power: 14 LED lights, 405nm UV | VIEW LATEST PRICE | See Our Full Breakdown |

| ANYCUBIC Wash and Cure 3 Plus for LCD/SLA/DLP Printers |  | Advanced Technology | Capacity: 4L cleaning and 4L curing (medium) | Compatibility: LCD, SLA, DLP printers including Photon Mono, Saturn | Curing Power: Flexicure gooseneck, 30,000 uW/cm² | VIEW LATEST PRICE | See Our Full Breakdown |

| ELEGOO Mercury Plus 2.0 Resin Wash & Cure Station |  | User-Friendly Design | Capacity: 5.16×3.54×8.66 inches (small/medium) | Compatibility: LCD, SLA, DLP printers up to 10 inches | Curing Power: 16 LED beads, 405nm UV, 360° rotation | VIEW LATEST PRICE | See Our Full Breakdown |

| ANYCUBIC Wash & Cure Machine 3.0 for LCD/DLP/SLA Printers |  | Compact & Efficient | Capacity: 4L cleaning bucket (medium) | Compatibility: Multiple resin LCD/SLA/DLP printers | Curing Power: 30,000 uW/cm², Gooseneck lights | VIEW LATEST PRICE | See Our Full Breakdown |

| ANYCUBIC Wash & Cure Station 3.0 for Resin 3D Printers |  | Professional Grade | Capacity: 4L cleaning capacity (medium) | Compatibility: LCD, SLA, MSLA, DLP resin printers | Curing Power: Flexicure gooseneck, 30,000 uW/cm² | VIEW LATEST PRICE | See Our Full Breakdown |

| ELEGOO Mercury Plus 2.0 Wash & Cure Station |  | All-in-One Solution | Capacity: 5L cleaning + curing (medium) | Compatibility: LCD, DLP, SLA printers, up to 10 inches | Curing Power: 16 UV LEDs, 405nm, 360° rotation | VIEW LATEST PRICE | See Our Full Breakdown |

| ELEGOO Mercury Plus Wash & Cure Station (230x135x260mm) |  | Heavy-Duty Capacity | Capacity: 7.5L cleaning + large curing (large) | Compatibility: LCD, SLA, DLP printers including Saturn, Mars | Curing Power: 24 LED UV, 405nm, rotating turntable | VIEW LATEST PRICE | See Our Full Breakdown |

| ANYCUBIC Wash & Cure 3 2-in-1 Station for Resin Printers |  | Versatile & Reliable | Capacity: 4L cleaning, supports larger models (medium) | Compatibility: LCD, SLA, DLP printers up to 7.3 inches | Curing Power: 30,000 uW/cm², Gooseneck lights | VIEW LATEST PRICE | See Our Full Breakdown |

More Details on Our Top Picks

ELEGOO Mercury X Wash & Cure Station Set

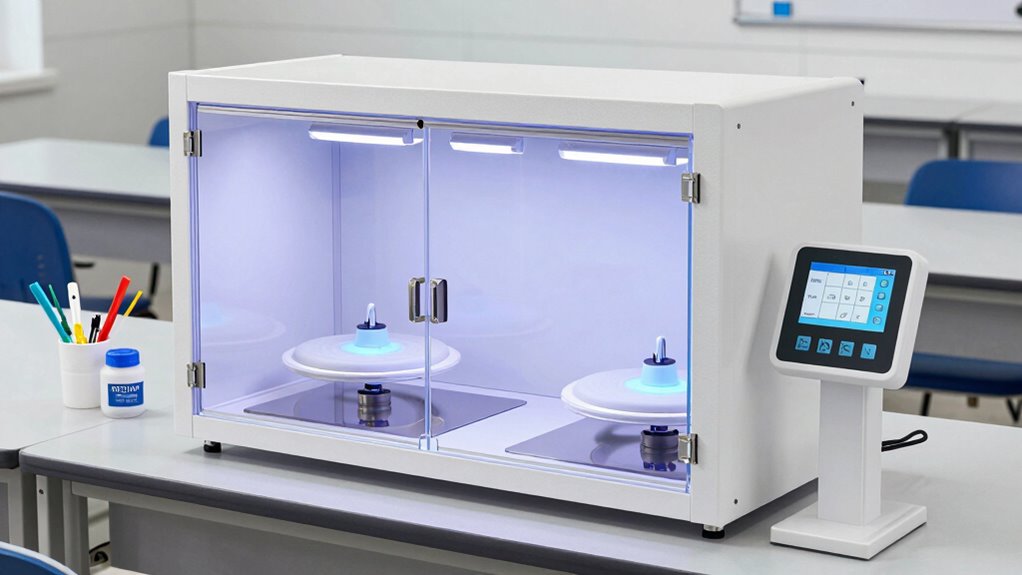

If you’re looking for a reliable solution to streamline your resin 3D print post-processing, the ELEGOO Mercury X Wash & Cure Station Set stands out as a top choice. It includes separate washing and curing units designed for efficiency and quality. The curing station features two LED light bars with Fresnel lenses and a rotating chassis, ensuring even curing for models up to Φ200mm×260mm. The washing station has a sealed design with an impeller for thorough cleaning, supporting models up to 180mm×121mm×153mm. Both units operate simultaneously via a dedicated adapter, making your workflow faster and more convenient.

- Capacity:Not specified (small/medium size)

- Compatibility:ELEGOO resin printers (Mars, Saturn)

- Curing Power:14 LED lights per bar, 405nm UV

- Operation Method:Manual dial, adjustable timers

- Size/Dimensions:Not specified

- Safety Features:Manual safety notes, review manual

- Additional Feature:Separate washing and curing stations

- Additional Feature:Supports simultaneous operation

- Additional Feature:Simple rotation-based timing adjustment

ANYCUBIC Wash & Cure Max 3.0 15.1L 3D Printer Station

The ANYCUBIC Wash & Cure Max 3.0 stands out as an ideal choice for professionals and serious hobbyists who need to process large resin prints efficiently. Its massive 15.1L chamber and compatibility with printers up to 13.6 inches allow for handling multiple or large models at once. The device offers automated, customizable wash and cure modes, saving time and effort. It uses advanced 360° spray rinsing and bottom cleaning to remove resin residue effectively while conserving detergent. The 360° rotating curing platform ensures uniform exposure, delivering high energy for thorough curing. Its user-friendly design and flexible settings make it perfect for demanding school makerspaces.

- Capacity:15.1L (large chamber)

- Compatibility:Most resin printers up to 13.6 inches

- Curing Power:25,000 μW/cm² UV energy

- Operation Method:Automatic with adjustable settings

- Size/Dimensions:Large chamber, 305 x 165 x 300mm

- Safety Features:Resin conservation, reduced detergent use

- Additional Feature:Auto and manual modes

- Additional Feature:Resin conservation technology

- Additional Feature:360° spray rinsing system

ELEGOO Mercury X Resin 3D Printer Wash & Cure

For resin 3D printing enthusiasts seeking a streamlined post-processing solution, the ELEGOO Mercury X Resin 3D Printer Wash & Cure stands out with its all-in-one design. It combines washing and curing into a single system, boosting efficiency and throughput. The large 7.5-liter container easily handles big prints, keeping models on the build plate while suspended on a hanger for thorough cleaning. The curing side features dual LED light bars with Fresnel lenses emitting 405nm UV light, ensuring high-quality results. Its simple interface and UV cover make operation safe and straightforward. For ideal results, dry models before curing, and avoid using water-washable resins in the washing unit.

- Capacity:7.5L (large capacity)

- Compatibility:ELEGOO Saturn, Mars MSLA

- Curing Power:14 LED lights, 405nm UV

- Operation Method:Manual knob, adjustable timers

- Size/Dimensions:7.5L container, dimensions not specified

- Safety Features:UV cover, safety protection

- Additional Feature:Wash remains on build plate

- Additional Feature:UV cover with safety protection

- Additional Feature:Supports large-scale prints

ANYCUBIC Wash and Cure 3 Plus for LCD/SLA/DLP Printers

With its large washing basket and increased capacity, the ANYCUBIC Wash and Cure 3 Plus stands out as an ideal choice for users operating multiple LCD, SLA, or DLP printers, especially those with build sizes up to 10.6 inches. Its upgraded washing area of nearly 9×5 inches and a 7.6-liter basket volume support various printer models like Photon Mono M5s and Saturn series. The device features advanced lighting with Flexicure gooseneck lights, providing 30,000 uW/cm² and improved curing uniformity. Its dual-layer curing platform boosts throughput, while the rust-resistant, adjustable cleaning basket maximizes efficiency, making it perfect for high-volume, professional post-processing.

- Capacity:4L cleaning and 4L curing (medium)

- Compatibility:LCD, SLA, DLP printers including Photon Mono, Saturn

- Curing Power:Flexicure gooseneck, 30,000 uW/cm²

- Operation Method:Single knob, automatic modes

- Size/Dimensions:8.97×5.03×10.23 inches

- Safety Features:Touch screen, safe operation

- Additional Feature:Dual-layer curing platform

- Additional Feature:Flexicure gooseneck light

- Additional Feature:Quiet operation (≤65dB)

ELEGOO Mercury Plus 2.0 Resin Wash & Cure Station

If you’re looking for an all-in-one solution that simplifies post-processing of resin prints, the ELEGOO Mercury Plus 2.0 stands out thanks to its integrated washing and curing functions. It features a rotary curing turntable, adjustable platform, and a washing bucket, supporting popular resin printers like ELEGOO Mars, Photon, QIDI, and NOVA. With 8 UV LED beads at 385nm and 405nm, it guarantees even curing through 360° rotation. The LCD touch screen makes setting curing times straightforward, while the anti-UV cover provides safety by blocking almost all UV rays. Despite being discontinued, it remains a professional, efficient choice for schools and makerspaces.

- Capacity:5.16×3.54×8.66 inches (small/medium)

- Compatibility:LCD, SLA, DLP printers up to 10 inches

- Curing Power:16 LED beads, 405nm UV, 360° rotation

- Operation Method:Touch screen, automatic/manual modes

- Size/Dimensions:Approx. 22.83 x 21.65 x 33.46 inches

- Safety Features:UV protection, automatic alert

- Additional Feature:Built-in 16 UV LED beads

- Additional Feature:Rotary curing turntable

- Additional Feature:Supports multiple resin printers

ANYCUBIC Wash & Cure Machine 3.0 for LCD/DLP/SLA Printers

The ANYCUBIC Wash & Cure Machine 3.0 stands out as an excellent choice for resin enthusiasts seeking efficient, large-capacity post-processing. Its innovative Flexicure Gooseneck Light boosts energy output by 30,000uW/cm², substantially improving local curing, while the upgraded light bead arrangement ensures 20% more uniform curing. With a spacious 165*100*180mm cleaning volume and support for models up to 160*180mm, it handles larger prints effortlessly. The dual-mode operation, adjustable timer, and flexible basket height make it versatile and user-friendly. Quiet and durable, this station is perfect for schools and makerspaces aiming for professional-grade post-processing.

- Capacity:4L cleaning bucket (medium)

- Compatibility:Multiple resin LCD/SLA/DLP printers

- Curing Power:30,000 uW/cm², Gooseneck lights

- Operation Method:Rotary knob, adjustable timers

- Size/Dimensions:Larger size, dimensions not specified

- Safety Features:Quiet operation, safe cleaning

- Additional Feature:Double-layer cleaning basket

- Additional Feature:Infinite 1-30 min adjustment

- Additional Feature:User-friendly interface

ANYCUBIC Wash & Cure Station 3.0 for Resin 3D Printers

Designed for resin 3D printing enthusiasts who demand efficient post-processing, the ANYCUBIC Wash & Cure Station 3.0 stands out with its upgraded cleaning and curing capacity. It features a 3-liter cleaning basket and a 4-liter total capacity, suitable for models up to 7.3 inches. Its dual-layer design supports simultaneous cleaning of platforms, while the Flexicure Gooseneck enhances curing efficiency by increasing energy output. The device offers adjustable curing times from 1 to 30 minutes, with improved light uniformity—20% better than previous models. Easy to operate and quieter during use, it’s perfect for both professional and hobbyist resin print finishing.

- Capacity:4L cleaning capacity (medium)

- Compatibility:LCD, SLA, MSLA, DLP resin printers

- Curing Power:Flexicure gooseneck, 30,000 uW/cm²

- Operation Method:Touch interface, modes switch

- Size/Dimensions:25 x 20 x 20 inches

- Safety Features:UV cover, safe operation

- Additional Feature:Double-layer PP cleaning basket

- Additional Feature:Quiet operation

- Additional Feature:Enhanced uniform curing

ELEGOO Mercury Plus 2.0 Wash & Cure Station

The ELEGOO Mercury Plus 2.0 Wash & Cure Station stands out for those seeking an all-in-one post-processing solution that saves time and space. It combines washing and curing functions in a single device, streamlining workflow and boosting productivity. The spacious build plate and washing basket accommodate larger or multiple models, making it versatile for various printers. Its advanced curing technology, with 16 UV LEDs and a rotating turntable, ensures quick and uniform results. Plus, features like quieter operation and reduced alcohol volatilization make it safer and more user-friendly. Overall, it’s a thorough, efficient choice for school makerspaces needing reliable post-processing.

- Capacity:5L cleaning + curing (medium)

- Compatibility:LCD, DLP, SLA printers, up to 10 inches

- Curing Power:16 UV LEDs, 405nm, 360° rotation

- Operation Method:Manual/auto modes, adjustable timers

- Size/Dimensions:Not specified

- Safety Features:UV shield, safety design

- Additional Feature:All-in-one post-processing

- Additional Feature:Large cleaning capacity

- Additional Feature:360° UV curing system

ELEGOO Mercury Plus Wash & Cure Station (230x135x260mm)

If you’re looking for a versatile solution for post-processing larger resin models, the ELEGOO Mercury Plus Wash & Cure Station stands out with its impressive 230x135x260mm cleaning capacity. This all-in-one device combines efficient resin cleaning, drying, and 360° UV curing, making it ideal for models up to 250mm in diameter and 290mm tall. Its vortex cleaning system effectively removes excess resin, while the rotating turntable ensures uniform curing with 24 LEDs and reflective mirror technology. The station offers two cleaning modes—basket and hanging—allowing safe, customizable workflows. Designed for resin printers up to 10 inches, it’s perfect for professional and hobbyist makers dealing with larger, complex models.

- Capacity:7.5L cleaning + large curing (large)

- Compatibility:LCD, SLA, DLP printers including Saturn, Mars

- Curing Power:24 LED UV, 405nm, rotating turntable

- Operation Method:Rotary knob, adjustable times

- Size/Dimensions:230 x 135 x 260mm

- Safety Features:UV protective cover

- Additional Feature:Mirror reflection technology

- Additional Feature:Disassembled model cleaning

- Additional Feature:Supports large models

ANYCUBIC Wash & Cure 3 2-in-1 Station for Resin Printers

For anyone working with larger resin models, the ANYCUBIC Wash & Cure 3 2-in-1 Station stands out thanks to its markedly increased capacity and compatibility. It features a 42% larger cleaning basket, fitting LCD printers up to 7.3 inches, with a 4-liter volume perfect for bigger prints. Its dual-layer PP basket with adjustable heights ensures efficient cleaning of various models. The device also improves curing uniformity by 20%, thanks to a new bead arrangement and enhanced light source, especially on detailed areas. Its quiet operation, flexible modes, and larger capacity make it an excellent choice for high-quality post-processing in busy makerspaces.

- Capacity:4L cleaning, supports larger models (medium)

- Compatibility:LCD, SLA, DLP printers up to 7.3 inches

- Curing Power:30,000 uW/cm², Gooseneck lights

- Operation Method:Rotary knob, adjustable 1-30 min

- Size/Dimensions:Approx. 20 x 20 x 25 inches

- Safety Features:UV protection, quiet operation

- Additional Feature:Larger cleaning basket

- Additional Feature:20% curing uniformity boost

- Additional Feature:Flexible platform heights

Factors to Consider When Choosing a Professional Resin Wash and Cure Station for School Makerspaces

When selecting a resin wash and cure station for a school makerspace, I focus on compatibility with our printers to guarantee smooth operation. I also consider capacity, ease of use, and safety features like UV protection to keep students safe and productive. Balancing curing efficiency with user-friendly design helps us choose the best station for our needs.

Compatibility With Printers

Choosing the right resin wash and cure station starts with guaranteeing it’s compatible with your school’s specific printer models. I recommend verifying support for your resin printer type—whether LCD, DLP, or SLA—to ensure seamless integration. It’s also essential to check the maximum build volume supported, so your largest models fit comfortably in the station. Compatibility with your resin types, like water-washable or standard resins, influences post-processing efficiency. Make sure the station’s cleaning and curing sizes match your typical print dimensions to avoid mismatches. Additionally, look for stations with adjustable platforms and multiple modes, which offer flexibility across different printer brands and models. Ensuring these factors will streamline your workflow and prevent compatibility issues, saving time and effort in your makerspace.

Capacity and Size Limits

Selecting a resin wash and cure station with appropriate capacity is crucial to keep your makerspace running smoothly. You need to ensure the maximum cleaning volume and curing size match or exceed the largest models produced in your space, preventing size limitations. Pay attention to the machine’s dimensions—height, width, and depth—to ensure it fits comfortably within your workspace and allows easy handling of larger prints. The capacity should support multiple or large models at once, boosting workflow efficiency, especially in busy educational environments. Features like adjustable platform heights and removable baskets can help accommodate various model sizes while optimizing cleaning and curing. Finally, consider the station’s overall footprint and compatibility with existing equipment to ensure seamless integration and smooth operation.

Curing Efficiency Features

To achieve ideal curing results in a school makerspace, it’s essential to focus on the station’s curing efficiency features. High-quality stations use powerful UV light sources at 385nm or 405nm wavelengths, ensuring thorough resin curing. Multi-directional light bars, rotating turntables, and Fresnel lenses promote uniform UV exposure, even on complex models. Adjustable curing times, often up to 30 minutes, give you precise control over curing strength and detail. Advanced stations incorporate high-intensity LED arrays and optimized light arrangements that cut down curing times without sacrificing quality. Features like automated rotation, adjustable platforms, and efficient light dispersion accelerate post-processing and minimize manual effort. These factors are vital for achieving consistent, professional results quickly in a busy school environment.

Ease of Use

When evaluating resin wash and cure stations for a school makerspace, ease of use plays a key role in ensuring smooth post-processing workflows. An intuitive interface with clear controls and presets makes operation straightforward, reducing the time needed for training students and staff. Touchscreen displays and automated functions allow for quick setup and adjustments, minimizing user errors during post-processing. Ergonomic design features, such as accessible buttons and adjustable platforms, promote safer and more efficient use by students of different ages. Automated modes with preset curing and washing cycles help produce consistent results, simplifying the process for beginners. Additionally, user-friendly maintenance features like easy cleaning access and clear indicator lights support ongoing device upkeep without requiring technical expertise, making these stations accessible for all users.

Safety and UV Protection

Ensuring safety and UV protection is crucial when choosing resin wash and cure stations for school makerspaces, as these devices emit ultraviolet light during curing processes that can pose health risks. UV-resistant covers or shields are essential to safeguard users from harmful rays. Enclosed stations with UV-blocking enclosures help prevent accidental exposure, creating a safer environment for students. It’s also important to look for safety certifications and compliance with industry standards, which indicate the device has been tested for UV safety and user protection. Automated UV shielding mechanisms or safety interlocks are valuable features—they prevent UV light from activating when the device is open or used improperly. In conclusion, clear safety instructions and warning labels should be included to educate users on potential risks and proper protective measures.

Cleaning Technology

Choosing the right resin wash and cure station for school makerspaces means paying close attention to cleaning technology. Advanced features like 360° spray rinsing and bottom-section cleaning ensure thorough removal of residual resin, even from tiny holes and intricate details. Dual cleaning modes, including automated spray and immersion, help optimize detergent use and minimize waste. Larger capacity chambers allow multiple or bigger models to be cleaned simultaneously, boosting efficiency. Look for systems with resin conservation features, which reduce detergent consumption and support sustainability. Effective curing systems with uniform UV light distribution and rotating platforms guarantee consistent hardening of all surfaces. These technological innovations not only improve cleaning accuracy but also streamline workflows, making them essential considerations when selecting a professional resin wash and cure station for educational settings.

Cost and Maintenance

Investing in a professional resin wash and cure station for school makerspaces involves more than just upfront costs; ongoing maintenance can considerably impact your budget and operation. Higher-quality stations often come with a higher initial price, ranging from several hundred to over a thousand dollars, depending on features and capacity. Maintenance expenses include replacement parts like UV LEDs, seals, and cleaning baskets, which are essential for consistent performance. Regular cleaning of components and replacing liquids or filters help prolong the device’s lifespan and ensure reliable results. Automated systems with self-cleaning functions can reduce manual effort but might be more costly to repair. Choosing a durable, well-built station with available spare parts minimizes unexpected repairs and downtime, making it a smarter long-term investment for school makerspaces.

Frequently Asked Questions

How Do Wash Stations Impact Overall Resin Print Quality?

Wash stations greatly improve resin print quality by thoroughly removing uncured resin, which reduces surface tackiness and enhances detail accuracy. I’ve noticed that proper washing prevents clouding and rough textures, resulting in smoother, more precise prints. Using a good wash station also minimizes manual handling, decreasing the risk of damage. Overall, investing in a quality wash station guarantees cleaner, more professional-looking prints that last longer and perform better.

Are There Eco-Friendly Resin Wash Options Available?

Absolutely, eco-friendly resin wash options are available and gaining popularity. I’ve researched these options, and many use biodegradable solvents or water-based cleaning solutions that reduce environmental impact. While they may require slightly different handling, they’re effective and safer for both users and the planet. Switching to eco-friendly washes not only supports sustainability but also encourages responsible practices in makerspaces. It’s a win-win for education and the environment.

What Safety Features Are Essential in School-Grade Wash & Cure Stations?

Safety features are vital in school-grade wash and cure stations. I always look for enclosed designs with proper ventilation to prevent harmful fumes. Overload protection and automatic shut-offs keep everyone safe during operation. Additionally, UV shielding is essential to protect students’ eyes and skin from exposure. Easy-to-use controls and clear warning labels also help guarantee safe handling, making the equipment both effective and safe for a school environment.

Can These Stations Handle Different Resin Types Simultaneously?

They can, but it’s like juggling different balls—you need a station with multiple curing chambers and adjustable settings. I recommend stations designed with separate compartments or customizable features so each resin type’s unique curing needs are met. Always check if the station explicitly states compatibility with various resins, as not all equipment is versatile. Proper ventilation and safety features are essential, especially when handling diverse resin materials at once.

What Maintenance Routines Ensure Longevity of Wash & Cure Equipment?

To keep your wash and cure stations lasting, I recommend regular cleaning with gentle, non-abrasive solutions and checking for any resin buildup. I always guarantee filters and vents are clear, and I follow the manufacturer’s maintenance schedule. Additionally, I inspect electrical connections and moving parts monthly, lubricate as needed, and avoid overloading the units. These routines help prevent breakdowns and extend the lifespan of your equipment.

Conclusion

Choosing the right resin wash and cure station is like finding the perfect tool to bring your creative garden to life. With so many options on the market, I hope this guide helps you pick the one that fits your makerspace’s needs. Remember, a good station isn’t just a tool—it’s the heartbeat of your 3D printing projects, turning raw ideas into polished masterpieces. Happy printing!