To turn your digital design into a precise physical model through laser cutting, you need to meticulously select the right material and optimize the laser settings for quality and intricacy. Accurate calibration of the laser equipment guarantees the geometry is transferred flawlessly, while controlling parameters like speed and power refines the details. Mastering these steps results in high-quality, intricate shapes that match your original design perfectly. Keep exploring to discover how these techniques come together seamlessly.

Key Takeaways

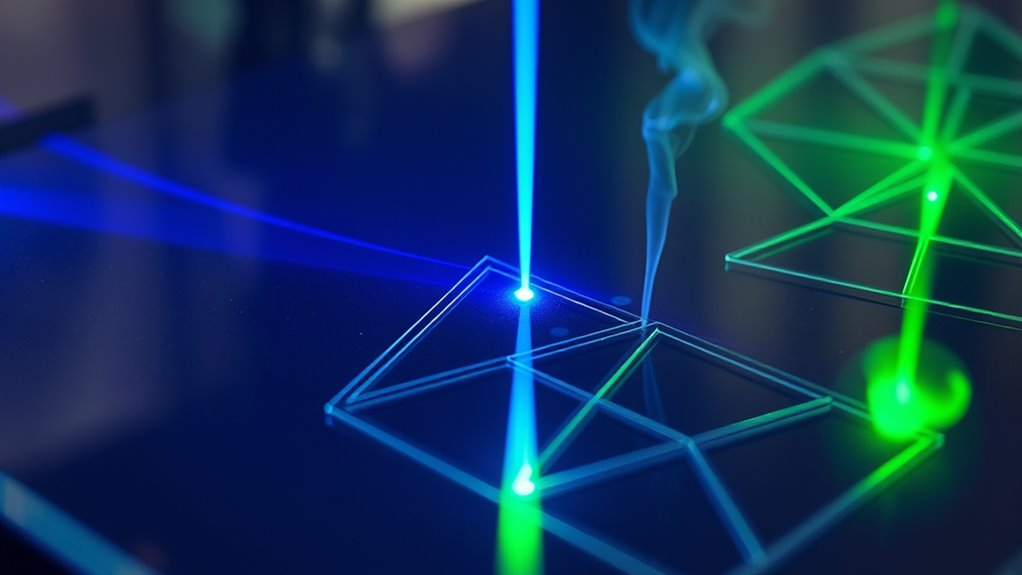

- Digital design files are translated into precise laser path instructions for accurate geometry reproduction.

- Material selection influences laser settings, ensuring geometric details are preserved during cutting.

- Laser calibration guarantees accuracy and minimal deviations in translating designs into physical models.

- Adjusting laser power and speed optimizes cut quality, capturing intricate geometric features.

- Proper process control transforms digital geometries into detailed, high-quality physical models.

Have you ever wondered how laser cutting achieves such precise and intricate designs? The secret lies in the careful interplay of material selection and cutting precision. When you choose the right material, you’re setting the foundation for a flawless cut. Different materials have unique properties that influence how they respond to laser energy. For instance, metals like stainless steel or aluminum require high-powered lasers and specific settings to guarantee clean, accurate cuts. Conversely, acrylic or wood might need different laser intensities to prevent burning or melting. Your choice of material directly impacts the quality of the final product, making material selection a vital step in the process.

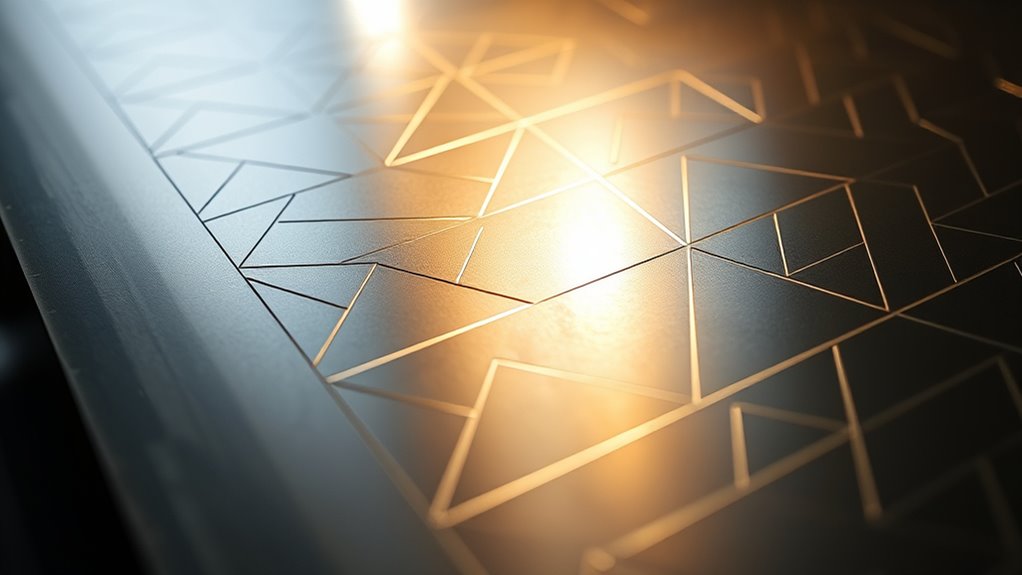

Once you’ve selected the appropriate material, the laser cutter’s cutting precision comes into play. This precision is achieved through a combination of advanced technology and meticulous calibration. The laser beam is focused into a narrow, intense point that can be moved with extreme accuracy across the material’s surface. As it traces the design you’ve created in your software, the laser melts, vaporizes, or burns away the material along the exact path you’ve set. The result is a clean, crisp cut with minimal deviation. The precision allows for complex geometries, detailed patterns, and tight tolerances that would be impossible with traditional cutting methods.

Your ability to manipulate the laser’s path and power settings further enhances cutting precision. Small adjustments can make a significant difference, especially when dealing with intricate designs. For example, reducing the laser’s power or speed in specific areas helps prevent overcutting or warping, ensuring every detail is preserved. This level of control is what transforms a simple digital design into a physical model with geometric accuracy. When working with different materials, you might need to tweak the settings to optimize the cut quality, but the core principle remains: precise control over the laser path guarantees high-quality results.

Additionally, understanding the properties of different materials, such as their melting points and absorption rates, can help optimize your laser cutting process for better results material properties. The combination of thoughtful material selection and precise laser control allows you to produce complex, detailed, and aesthetically pleasing designs. It’s this mastery over the process that turns your digital files into tangible, geometric models with exacting accuracy. As you refine your technique and understand the characteristics of various materials, you’ll continually improve your ability to produce high-quality, intricate cuts. Laser cutting isn’t just about technology; it’s about your skill in selecting the right materials and wielding the laser with precision, making your creative visions a reality with unmatched accuracy.

Frequently Asked Questions

How Does Laser Cutting Affect Material Properties Over Time?

Laser cutting can cause material fatigue and surface degradation over time. You might notice cracks or weakening around the cut edges as the material experiences stress and environmental exposure. The intense heat from laser cutting alters the surface structure, making it more prone to corrosion and wear. To minimize these effects, guarantee proper post-processing and avoid excessive use in demanding environments, helping your material maintain its integrity longer.

Can Complex Geometries Be Achieved With Standard Laser Cutters?

Yes, with standard laser cutters, you can achieve intricate patterns, but design constraints may limit complexity. These machines excel at precision, allowing detailed geometries, but factors like material thickness and machine power can restrict the level of intricacy. You need to optimize your design for the cutter’s capabilities, ensuring your complex geometries are feasible within the equipment’s limits. Proper planning helps you create impressive detailed models efficiently.

What Are the Limitations of Laser Cutting for Large-Scale Models?

When creating large-scale models, you’ll face scaling challenges and material size limitations with laser cutting. For example, a cityscape sculpture might require cutting multiple panels that need seamless assembly, but the laser cutter’s bed size caps the maximum material dimensions. This means you’ll need to piece parts together, which can affect precision and increase assembly time. Large projects demand careful planning to overcome these inherent size constraints.

How Do Design Software Choices Influence Laser Cutting Precision?

Your choice of design software directly impacts laser cutting precision by affecting software compatibility and how well it handles intricate designs. If your software easily integrates with your laser cutter and supports detailed geometry, you’ll achieve cleaner cuts and finer details. Conversely, incompatible or limited software can cause misalignments or jagged edges, especially with complex designs. Always select software that aligns with your equipment and matches your design complexity for ideal results.

Are There Safety Concerns Specific to Laser Cutting Intricate Designs?

Yes, there are safety concerns with intricate designs in laser cutting. You should be aware of laser safety risks like fumes and potential fire hazards, especially with complex, detailed patterns that can trap heat or cause uneven cuts. Always wear proper safety gear, ensure good ventilation, and monitor the process closely. Managing design complexity helps prevent accidents, guaranteeing your workspace stays safe while achieving precise, intricate results.

Conclusion

As you explore laser cutting and geometry, you gently open the door to endless creative possibilities. While the process might seem intricate at first, it subtly guides you toward turning your ideas into tangible masterpieces. Embrace the journey, knowing that each step brings you closer to flawless precision and innovative design. With a little patience and curiosity, you’ll discover how this technology quietly transforms visions into mesmerizing physical models, inviting you to imagine even greater creations ahead.