To guarantee your vacuum-formed molds release cleanly every time, focus on designing smooth, polished surfaces with proper draft angles to help parts separate easily. Use non-porous materials like acrylic, apply appropriate release agents, and avoid undercuts or complex features that trap parts. Regularly maintain and clean your molds to prevent sticking issues. If you’re interested, exploring detailed techniques can help you optimize your mold designs for better results.

Key Takeaways

- Incorporate draft angles and smooth, polished surfaces to facilitate easy part release.

- Use non-porous, low-adhesion mold materials and apply compatible release agents regularly.

- Design molds with features that minimize undercuts and avoid complex geometries trapping parts.

- Ensure proper surface finishes and coatings to reduce adhesion and promote smooth separation.

- Maintain molds through cleaning and inspection, reapplying release agents as needed for consistent releases.

What Is Vacuum Forming and How Does It Work?

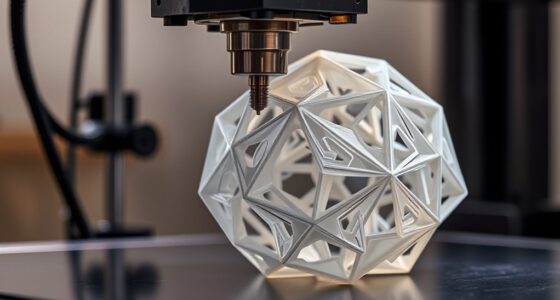

Have you ever wondered how plastic sheets are shaped into complex forms so smoothly and quickly? That’s the magic of vacuum forming. This process involves heating a plastic sheet until it becomes pliable, then draping it over a mold. A vacuum pulls the sheet tightly onto the mold, creating a precise, detailed shape. Once cooled, the plastic hardens into its new form. To guarantee easy mold release, manufacturers often use mold release agents, which prevent the plastic from sticking. Vacuum forming is efficient and cost-effective for producing large quantities of consistent parts. It’s ideal for creating prototypes, packaging, and custom enclosures. Understanding how vacuum forming works helps you appreciate the importance of proper mold release techniques for clean, high-quality results every time. Additionally, considering the free floating design concept can lead to more natural and seamless product aesthetics. Proper mold design and material selection are critical for achieving optimal results and minimizing defects in the final product. Furthermore, employing appropriate temperature control during the process ensures better surface finish and reduces warping or defects. Incorporating clamping systems can also improve sheet tension and uniformity during forming, leading to higher quality outcomes, especially when combined with proper tooling for precision.

How to Design Molds for Easy Release and High-Quality Parts

Designing molds for vacuum forming requires careful attention to detail to guarantee easy release and high-quality parts. One key factor is selecting the right mold release strategies, which can include applying suitable surface coatings. These coatings reduce friction between the mold and the thermoplastic, preventing sticking and ensuring smooth part removal. When choosing surface coatings, consider their compatibility with your mold material and the forming temperature. Properly finished mold surfaces, combined with effective mold release agents, minimize defects like tearing or warping. Additionally, ensuring the mold surface is smooth and free of imperfections promotes consistent part quality. Implementing simple surface treatments can also enhance mold release efficiency and extend the lifespan of your tools. For optimal results, it’s important to consider mold surface finish when designing your mold, as it significantly impacts the ease of release and final part quality. Prioritizing surface coatings and release techniques helps prevent damage to the parts and reduces production downtime. Incorporating appropriate surface treatments can further improve mold longevity and performance. Understanding the importance of reliable mold release strategies is essential for maintaining production flow and achieving high-quality outcomes. By focusing on surface coatings and mold release techniques, you’ll streamline production, improve part quality, and extend your mold’s lifespan.

What Materials and Surface Finishes Promote Mold Release?

Choosing the right materials and surface finishes is essential for promoting easy mold release in vacuum forming. Selecting smooth, non-porous materials like acrylic or polycarbonate helps prevent sticking. Applying mold coatings can create a slick surface that reduces adhesion. Using compatible release agents can further ease part removal, especially with complex shapes or textured surfaces. Some mold coatings are specifically designed to enhance release, making the process smoother and reducing the risk of damage. Proper surface finishes, such as polishing or applying a thin film of mold release spray, can substantially improve part release and extend mold life. Additionally, understanding the surface energy of mold materials can help optimize release properties and minimize defects. Incorporating surface treatments that modify the mold surface can effectively reduce friction and improve release. Understanding the material compatibility of coatings and release agents ensures they do not adversely react with mold surfaces or affect part quality. Regular maintenance and cleaning of mold surfaces also help maintain optimal release performance over time. Remember, a well-finished surface minimizes friction and sticking, ensuring your parts come out cleanly and the mold stays in good condition for repeated use.

Simple Tips to Prevent Sticking and Extend Mold Life

To prevent sticking and extend mold life during vacuum forming, you should focus on proper maintenance and handling practices. Regular mold cleaning removes residue, debris, and buildup that can cause sticking. Use appropriate cleaning methods to avoid damaging the mold surface. Applying effective release agents consistently creates a barrier that helps parts release smoothly and reduces wear. Make sure to select release agents compatible with your mold material and plastic sheet. Always clean the mold thoroughly before applying new release agents to ensure peak performance. Proper handling also means avoiding scratching or gouging the mold surface, which can compromise release effectiveness. Additionally, understanding the mold terminology can help you identify issues early and maintain your equipment more effectively. Regular inspections and understanding mold wear can further help you detect early signs of deterioration. Being aware of mold maintenance routines ensures your equipment stays in optimal condition and prevents costly damages. Monitoring mold temperature during the forming process is crucial, as temperature fluctuations can impact release and mold longevity. Incorporating sound techniques such as gentle tapping or vibrations can sometimes aid in releasing parts more smoothly and prevent sticking. By maintaining a clean mold and using quality release agents, you’ll minimize sticking issues and prolong your mold’s lifespan.

How to Troubleshoot Common Mold Release Problems?

When you encounter mold release problems, quick and accurate troubleshooting can save time and prevent damage to your parts. First, check if your mold needs cleaning—residual debris or old release agents can cause sticking. Use appropriate mold cleaning techniques to remove buildup without damaging the surface. Next, evaluate your release agents; if they’re old or improperly applied, they won’t work effectively. Reapply a fresh, even coat of release agent, ensuring full coverage. Proper maintenance practices can also prevent issues before they occur. If parts still stick, consider whether the release agent is compatible with your mold material. Sometimes, switching to a different type or increasing the application frequency helps. Regular cleaning and proper release agent application are key to preventing future issues and achieving consistent, clean releases every time. Additionally, understanding mold maintenance practices can greatly improve your success rate. Incorporating mold design considerations can also minimize sticking problems and facilitate easier releases.

Frequently Asked Questions

What Are the Best Practices for Cleaning Molds Between Uses?

To guarantee easy mold cleaning between uses, always remove debris with a soft brush or compressed air first. Use a mild detergent and warm water for cleaning, avoiding harsh chemicals that could damage the mold. Apply a light coating of release agents after cleaning to prevent sticking. Regularly inspect for residue or damage, and keep molds dry to maintain ideal release performance.

How Do Temperature Variations Affect Mold Release Efficiency?

Imagine your mold as a delicate dance partner—temperature variations can throw off the rhythm. When temperatures fluctuate, it disrupts temperature stability, making mold release less smooth. Too hot or cold, and materials may stick or crack. To keep the dance flowing, guarantee consistent temperatures and check material compatibility. This harmony helps your molds release cleanly every time, turning your vacuum forming process into a seamless performance.

Can Mold Release Agents Be Applied to Improve Results?

Yes, applying mold release agents can improve your results by ensuring easier, cleaner releases. Choose a release agent compatible with your mold surface to prevent damage or residue buildup. Surface compatibility is essential; using the wrong agent may cause sticking or surface deterioration. Always test the release agent on a small area first, and follow the manufacturer’s instructions for best results, especially when working with temperature variations.

What Safety Precautions Should Be Taken During Mold Preparation?

Think of safety as your shield, like a knight preparing for battle. You should always wear personal protective equipment, such as gloves, goggles, and masks, to guard against fumes and debris. Make certain your workspace is well-ventilated to disperse harmful vapors. Keep a clean, organized area, and follow manufacturer guidelines. These precautions protect your health and ensure smooth mold preparation, just as a knight safeguards their armor before combat.

How Do I Choose the Right Mold Design for Complex Shapes?

When selecting a mold design for complex shapes, consider the mold material’s flexibility and durability to handle intricate details. Opt for designs that incorporate undercuts and smooth progression, which facilitate easier release. You should also assess the design complexity to guarantee the mold can accurately replicate detailed features without causing sticking or damage. Balancing detailed features with manufacturability will help you create effective, clean-release molds for complex shapes.

Conclusion

Mastering mold design is your secret weapon for flawless vacuum-formed parts every time. By focusing on easy-release features and proper materials, you’ll prevent sticking like magic—and extend your mold’s life beyond your wildest dreams. With these tips, you’ll turn challenging projects into smooth successes and become a true vacuum forming pro. Don’t settle for mediocre results—aim for perfection that blows everyone away. Your perfect, clean releases are just a well-designed mold away!