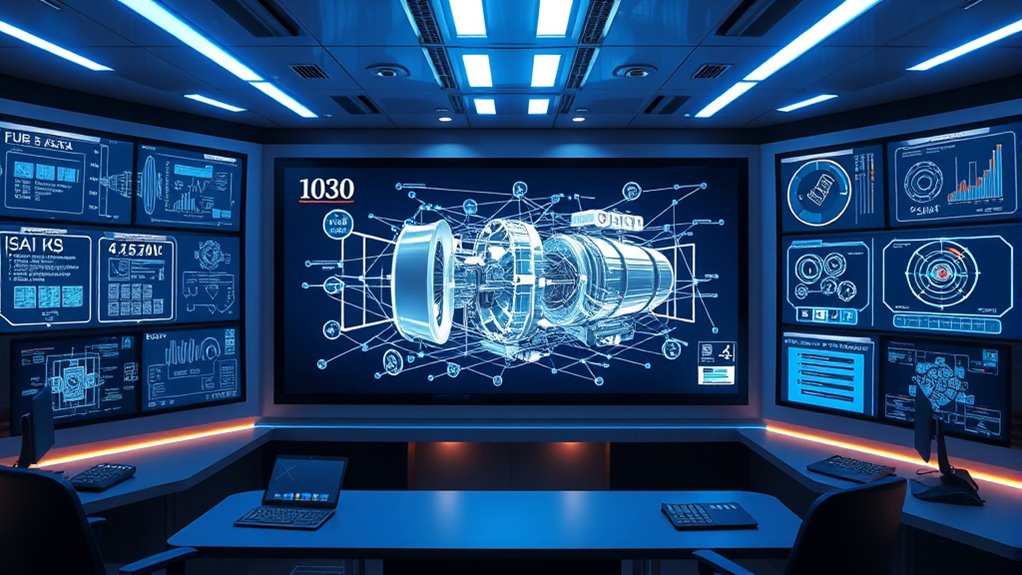

In Industry 4.0, digital twins use detailed geometric data to simulate physical assets accurately. This precise geometry helps you predict performance, identify design flaws early, and optimize for durability and efficiency. It also enables you to perform real-time tweaks and what-if analyses, improving decision-making and reducing costs. By continuously integrating sensor data, these models stay accurate and support proactive maintenance. Keep exploring how geometry enhances digital twin simulations for smarter, more resilient operations.

Key Takeaways

- Digital twins utilize detailed geometrical data to accurately simulate asset behavior under various conditions.

- Precise geometry enables analysis of stress, airflow, and thermal properties for optimized design.

- Geometry-based simulations allow for real-time modifications and what-if scenario testing.

- Continuous geometrical data from sensors enhances model accuracy and predictive maintenance capabilities.

- Accurate geometry improves performance prediction, reduces costs, and accelerates development in Industry 4.0.

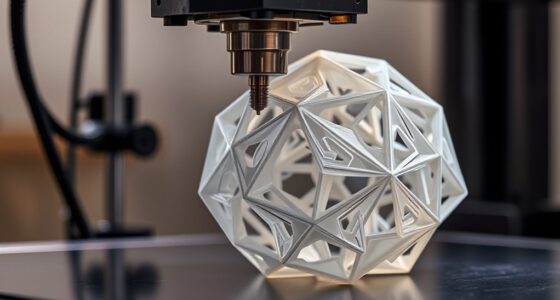

Digital twins have become a cornerstone of Industry 4.0, transforming how manufacturers design, monitor, and optimize their operations. Through virtual prototyping, you can create detailed digital replicas of physical assets, allowing you to simulate their behavior in a virtual environment before any physical production begins. This process enables you to identify design flaws early, test different configurations, and make informed decisions without costly physical prototypes. Virtual prototyping accelerates development cycles and reduces expenses, giving you a competitive edge by bringing innovative products to market faster.

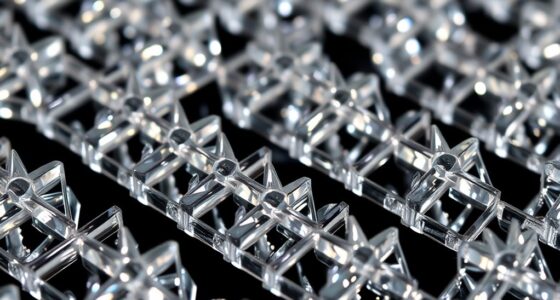

Moreover, digital twins leverage precise geometry to simulate real-world scenarios with remarkable accuracy. The detailed geometrical data allows you to analyze stress points, airflow, thermal properties, and other critical factors in a controlled virtual setting. By doing so, you optimize the design for performance, durability, and efficiency, minimizing the risk of failures once the product is in use. This geometrical precision forms the backbone of predictive maintenance strategies, which are essential for keeping your operations running smoothly. With a digital twin, you can monitor the condition of machinery in real time, predict when maintenance is needed, and schedule interventions proactively. This reduces downtime, prevents costly breakdowns, and extends the lifespan of your equipment.

You’ll find that the integration of geometry-based simulations enhances your ability to perform what-if analyses. When you modify a component or operational parameter in the digital twin, the system instantly updates to show potential impacts on performance and longevity. This dynamic feedback loop helps you make data-driven decisions, refine processes, and improve overall system resilience. It’s like having a crystal ball that shows the future condition of your assets, allowing you to act before problems escalate.

Furthermore, these geometric simulations aren’t just static; they adapt as real-world data flows into the digital twin. Sensors collect information from physical assets, feeding precise geometrical and operational data back into the model. This continuous cycle ensures your digital twin remains an accurate reflection of reality, enhancing predictive maintenance accuracy and operational insights. As a result, you gain an extensive understanding of your systems, enabling you to optimize workflows, reduce waste, and boost productivity.

In addition, the use of detailed geometry helps in accurately predicting how physical assets will perform under various conditions, which is crucial for effective cost management. In essence, the power of geometry in digital twins transforms how you approach product development and maintenance. Virtual prototyping speeds up innovation, while predictive maintenance minimizes downtime—both driven by highly detailed, geometry-based simulations. This integration of digital and physical worlds puts you at the forefront of Industry 4.0, making your operations smarter, more efficient, and more resilient.

Frequently Asked Questions

How Do Digital Twins Adapt to Real-Time Environment Changes?

You can guarantee your digital twins adapt to real-time environment changes by integrating sensors that continuously collect data. These sensors feed live information into the twin, allowing it to update instantly. Data synchronization keeps the digital model aligned with actual conditions, enabling you to monitor and respond proactively. This seamless connection ensures your digital twin reflects real-world dynamics, supporting better decision-making and system optimization.

What Are the Main Challenges in Implementing Digital Twins at Scale?

Implementing digital twins at scale is like building a vast, intricate puzzle, with data integration and scalability challenges as the tricky pieces. You might struggle to connect diverse data sources seamlessly and guarantee systems grow without crashing. To succeed, focus on robust infrastructure, standardized data protocols, and flexible architectures. Overcoming these hurdles lets you harness full potential, transforming operations into a well-oiled machine with real-time insights.

How Does Geometry Influence the Accuracy of Simulations?

Geometry directly influences the accuracy of your simulations through geometric precision and spatial modeling. When you use detailed and precise geometric data, your digital twin reflects real-world conditions more accurately. High-quality spatial modeling captures complex shapes and relationships, reducing errors. Conversely, imprecise geometry leads to unreliable results. To improve simulation fidelity, focus on refining geometric details and ensuring your models accurately represent the physical assets involved.

Can Digital Twins Predict Future System Failures Accurately?

You can trust digital twins to predict future system failures accurately if you keep data synchronization tight and leverage predictive maintenance techniques. They mirror real-world conditions so well that they’re often ahead of the curve, catching issues before they happen. While no tool is foolproof, combining real-time data with advanced modeling makes digital twins a reliable crystal ball for maintenance planning and preventing costly downtimes.

What Industries Benefit Most From Digital Twin Technology Integration?

You’ll find manufacturing, aerospace, and automotive industries benefit most from digital twin technology. It helps you optimize manufacturing processes and perform predictive maintenance effectively. By creating accurate virtual models, you can simulate scenarios, identify potential issues early, and improve overall efficiency. Digital twins enable you to reduce downtime, lower costs, and enhance product quality, making them essential tools for industries aiming to stay competitive and innovative in today’s digital landscape.

Conclusion

By leveraging digital twins that utilize precise geometry for simulations, you can optimize manufacturing processes and reduce downtime. Did you know that companies implementing digital twins see up to a 30% increase in operational efficiency? Embracing Industry 4.0 tools like these not only boosts productivity but also enhances predictive maintenance. So, integrating digital twins into your workflow isn’t just a smart move — it’s essential for staying competitive in today’s digital landscape.