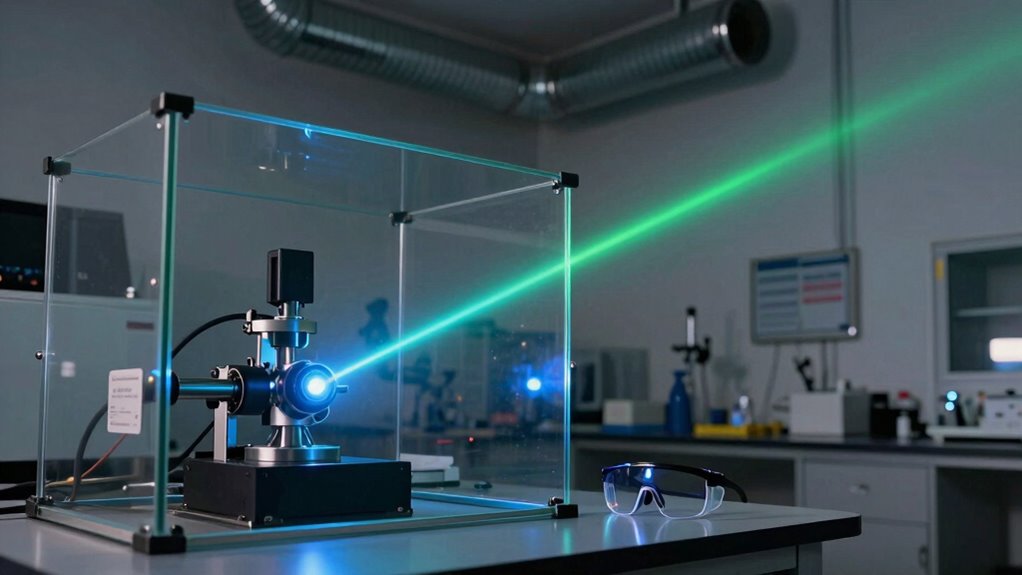

Laser safety isn’t optional because proper ventilation, enclosures, and eye protection are essential for preventing serious injuries and hazards. Ventilation system reduces harmful fumes and airborne particles, while enclosures contain laser beams and spills, acting as barriers. Wearing the right protective eyewear filters harmful wavelengths and prevents eye damage. Ignoring these safety measures increases risk. To learn how these elements work together to keep you safe, keep exploring these critical safety practices.

Key Takeaways

- Proper ventilation and air filtration systems reduce toxic fumes and airborne contaminants during laser operations.

- Enclosures physically contain laser beams, preventing accidental exposure and containing hazards effectively.

- Wearing appropriate protective goggles filters harmful wavelengths, safeguarding eyes from direct and reflected laser beams.

- Regular maintenance and safety checks ensure equipment functions correctly, minimizing risks of misalignment and failures.

- Establishing a safety culture with signage, training, and protocols enhances awareness and prevents common laser safety mistakes.

Why Laser Safety Is Critical in Every Setting

Laser safety is essential in every setting because exposure to laser beams can cause serious eye and skin injuries. Developing a strong laser safety culture helps everyone understand the importance of precautions and responsible behavior around lasers. Clear laser safety signage plays a vital role by alerting you to potential hazards and reminding you to follow safety protocols. When everyone actively participates in maintaining safety standards, the risk of accidents decreases considerably. Proper signage ensures that laser hazards are visible and understood, fostering awareness at all times. A proactive laser safety culture encourages safe practices, reduces mishaps, and protects your health. Additionally, understanding the contrast ratio of projectors can help in assessing the visibility of safety signs in different environments. Incorporating innovative European cloud servers can further support comprehensive safety data management and training programs. Ensuring proper ventilation systems are in place is crucial for dispersing potentially harmful laser fumes and maintaining a safe workspace. Effective hazard communication methods, such as visual indicators, can enhance real-time hazard communication, further strengthening safety protocols. Ultimately, prioritizing laser safety in your environment keeps you and your colleagues safe while allowing you to work confidently with laser technologies.

What Are the Main Laser Hazards and Risks?

Understanding the main hazards and risks associated with laser use is essential for maintaining safety. The primary danger is the laser beam itself, which can cause serious injuries if not properly controlled. Key risks include:

- Eye damage: Direct or reflected laser beams can permanently harm your eyes, leading to vision loss.

- Skin burns: High-powered lasers can cause skin burns upon contact, especially with prolonged exposure.

- Fire hazards: Intense laser beams can ignite flammable materials nearby, creating fire risks.

Being aware of these hazards helps you implement safety measures like proper enclosures and protective gear. Recognizing these risks ensures you stay vigilant, preventing accidents and injuries during laser operation. Proper ventilation is also crucial to prevent the buildup of potentially harmful fumes produced during laser cutting or engraving.

How Ventilation Protects Against Laser Fumes and Particles

Proper ventilation plays a crucial role in protecting you from hazardous fumes and particles generated during laser operations. When you use effective air filtration systems and fume extraction, you reduce the concentration of airborne contaminants that can pose health risks. Fume extractors capture particles at the source, preventing them from dispersing into your workspace. Air filtration units then remove remaining fumes and fine particles from the air, ensuring cleaner, safer conditions. Adequate ventilation not only improves air quality but also minimizes exposure to potentially toxic substances. By integrating these systems into your laser setup, you create a safer environment for yourself and others, reducing long-term health hazards associated with inhaling harmful fumes and particles. Proper ventilation is an essential part of all-encompassing laser safety.

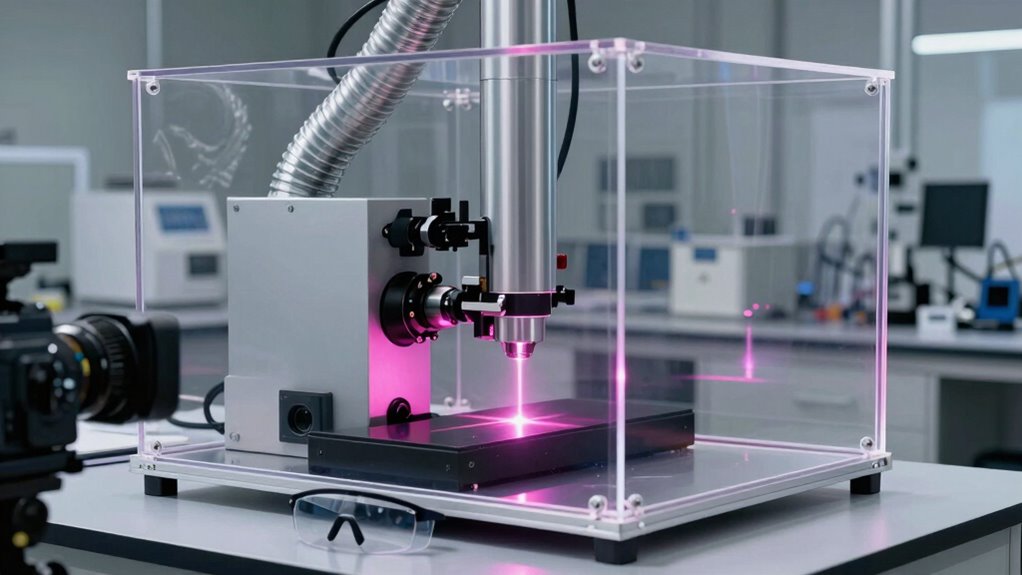

Why Enclosures Keep Laser Beams and Spills Contained

Enclosures are essential for containing laser beams and preventing accidental exposure. They serve as a physical barrier that guarantees beam containment and spill prevention, reducing risks in your workspace. Without proper enclosures, laser spills can escape, posing hazards to you and others nearby. To maximize safety, focus on these key points:

- Use sealed enclosures that fit tightly around the laser apparatus to prevent leaks.

- Incorporate interlocks that automatically shut off the laser if the enclosure is opened.

- Regularly inspect enclosures for cracks or damage that could compromise spill prevention.

- Ensure that enclosures are made of appropriate materials that resist laser damage and contain potential spills effectively.

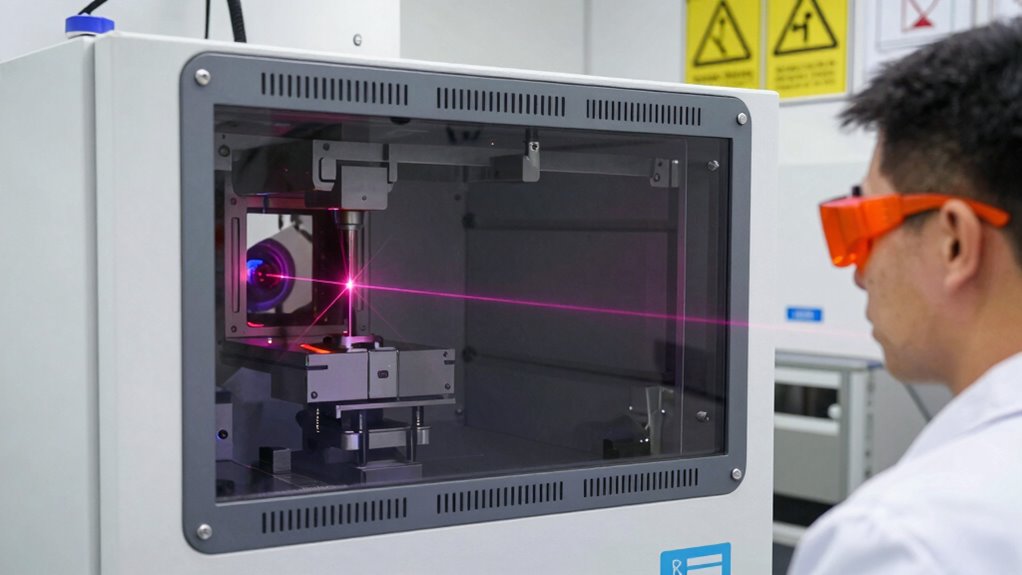

Why You Need Proper Eye Protection When Using Lasers

When working with lasers, your eyes are among the most vulnerable parts of your body. Even a small laser beam reflection can cause serious eye injury if you’re unprotected. Laser beams can reflect off shiny surfaces or unintended objects, directing intense light straight into your eyes. Without proper eye protection, you risk damage that may be temporary or permanent, including burns or retinal injuries. Wearing appropriate laser safety goggles helps prevent these injuries by filtering out harmful wavelengths and reducing exposure. Eye injury prevention is essential for safe laser operation, as accidental exposure can happen quickly and without warning. Investing in quality protective eyewear ensures you safeguard your vision while working with lasers, helping you avoid costly, painful, and potentially lifelong consequences. Taking proactive safety measures, such as using laser safety protocols, is crucial to minimize risks and ensure a safe working environment. Proper ventilation and enclosures also play a vital role in dispersing hazardous fumes and stray beams, further enhancing safety measures. Additionally, understanding laser classification can help you choose the appropriate safety equipment and procedures for your specific laser type. Being aware of the potential for reflection hazards emphasizes the importance of using protective barriers and maintaining a clean workspace to reduce accident risks. Furthermore, recognizing the importance of training can significantly improve safety practices and help prevent accidental injuries.

How to Choose the Right Laser Safety Equipment

Choosing the right laser safety equipment is essential to protect yourself effectively during laser operations. First, identify the laser’s wavelength and power to select appropriate laser safety gear. Second, evaluate the environment—whether it’s a lab or workshop—and choose enclosures or barriers accordingly. Third, invest in high-quality protective eyewear that matches your laser’s specifications, ensuring it filters out harmful wavelengths. Remember, not all protective eyewear offers the same level of protection, so verify their optical density and certification. The right combination of safety gear, including enclosures and protective eyewear, minimizes risks and keeps you safe. Always consult manufacturer guidelines and safety standards to make informed decisions about your laser safety equipment. Additionally, understanding laser terminology helps in choosing equipment that meets specific safety requirements. Knowing the classification of lasers also guides you in selecting the appropriate safety measures based on laser class and potential hazards.

Best Practices for Developing and Enforcing Laser Safety Protocols

To keep everyone safe, you need to establish clear laser safety procedures and make certain they’re understood. Regular training helps staff stay updated on protocols and safety practices. By enforcing consistent rules, you reduce the risk of accidents and ensure a safe laser environment. Incorporating proper ventilation and protective enclosures further enhances safety measures. Additionally, understanding air quality considerations can significantly mitigate potential hazards associated with laser operations. Maintaining air quality is essential for preventing the buildup of harmful fumes and ensuring a healthier workspace. Implementing comprehensive safety protocols also demonstrates a commitment to ethical standards, which can foster trust and credibility among team members. Ensuring proper ventilation systems are in place can further improve overall safety and air quality during laser use.

Establish Clear Procedures

Establishing clear procedures is essential for maintaining a safe laser environment. You should create detailed protocols that everyone follows consistently. To do this effectively, focus on three key steps:

- Develop thorough safety checklists to ensure all safety measures are reviewed before each operation.

- Implement a straightforward incident reporting system so hazards or accidents are documented immediately.

- Enforce strict adherence to procedures through regular audits and accountability checks.

Clear procedures help prevent accidents and ensure quick responses to safety concerns. They also foster a safety-conscious culture. By emphasizing safety checklists and incident reporting, you reduce risks and improve overall laser safety. Consistent enforcement of these procedures keeps your workspace secure for everyone involved.

Conduct Regular Training

Regular training is essential to guarantee everyone understands laser safety protocols and follows them consistently. You should schedule ongoing sessions to keep staff updated on proper laser maintenance procedures and safety practices. These trainings reinforce the importance of protective gear, safe handling, and emergency procedures. Effective staff communication is crucial; ensure everyone feels comfortable asking questions and reporting hazards. Regular refreshers help identify gaps in knowledge and reinforce a safety culture. Incorporating real-world scenarios makes training practical and memorable. Consistent training minimizes risks, prevents accidents, and ensures compliance with safety standards. Additionally, understanding water safety is vital, especially in environments where water is used for cooling or other purposes near laser equipment. By prioritizing ongoing education, you foster a safer environment where laser safety protocols become second nature to all team members. Recognizing hazard identification as a key component further enhances overall safety awareness and preparedness.

Common Laser Safety Mistakes and How to Avoid Them

One of the most common laser safety mistakes is overlooking proper eye protection, which can lead to serious injuries. Another mistake is neglecting regular maintenance, increasing risks of beam misalignment and equipment failure. To avoid these pitfalls:

- Always inspect and calibrate your laser setup before use to prevent beam misalignment.

- Follow a strict maintenance schedule to keep safety features and enclosures functioning properly.

- Never bypass safety protocols or assume equipment is safe without verification.

- Understanding the importance of proper safety practices can significantly reduce the risk of accidents and ensure safe operation in your laser activities. Incorporating energetic alignment principles can also enhance the overall safety and effectiveness of your setup.

- Regularly checking safety features and ensuring they are functioning correctly is crucial for maintaining a safe environment. Beam misalignment can expose you to harmful laser radiation, so regular checks are essential. Maintenance neglect can cause unexpected hazards or equipment malfunction. Staying vigilant and proactive helps protect your eyes and reduces accident risks. Conducting routine safety checks is vital for ongoing safety and compliance. Proper safety habits are your best defense against common mistakes.

- Additionally, understanding the regulatory standards for laser equipment can help ensure compliance and safety in your workplace.

Frequently Asked Questions

What Are the Legal Requirements for Laser Safety Compliance?

You must follow laser safety regulations set by OSHA, ANSI, and other authorities to guarantee compliance. This includes maintaining proper ventilation, using enclosures, and providing eye protection. Keep detailed compliance documentation of safety measures, training, and inspections to demonstrate adherence. Regularly review and update protocols to meet evolving standards. By actively implementing these requirements, you protect yourself and others while avoiding legal penalties.

How Often Should Laser Safety Equipment Be Inspected or Replaced?

Have you checked your laser safety equipment recently? You should inspect and replace it regularly—typically every 6 to 12 months—depending on usage and manufacturer recommendations. Laser maintenance and proper equipment calibration are essential to make certain safety. Are you keeping detailed records of inspections? Regular checks help prevent malfunctions and ensure compliance, so stay proactive in maintaining your safety gear to protect yourself and others from potential hazards.

Can Laser Safety Measures Vary Between Industrial and Medical Settings?

Yes, laser safety measures vary between industrial and medical settings. In industrial environments, you’ll need specific types of protective gear like heavy-duty goggles and safety enclosures, along with clear hazard signage to alert personnel. Medical settings require more specialized eye protection and controlled access. Always tailor your safety protocols to the setting, ensuring that hazard signage is visible and protective gear matches the laser’s power and application to prevent accidents.

What Training Is Necessary for Personnel Operating Laser Equipment?

Think of laser safety training as your shield in a battlefield. You must complete thorough laser safety training and obtain personnel certification before operating laser equipment. This training covers proper handling, safety protocols, and emergency procedures, ensuring you understand risks and protective measures. By staying certified, you keep yourself and others safe, turning potential hazards into manageable risks and making sure laser use remains controlled and secure.

Are There Specific Standards Governing Laser Safety in Different Countries?

You should know that specific standards governing laser safety vary across countries, but international regulations often set the baseline for safety. You need to make sure your equipment meets these standards and obtain appropriate safety certification. Staying compliant means regularly reviewing and adhering to local laws and international guidelines, which helps protect everyone involved and prevents legal issues. Always check the relevant regulations before operating laser equipment in different jurisdictions.

Conclusion

Remember, laser safety isn’t just a checklist—it’s your shield in a world of focused beams and hidden hazards. Think of ventilation, enclosures, and eye protection as your trusted guardians, dancing in harmony to keep you safe. When you prioritize these measures, you’re weaving a protective tapestry that keeps danger at bay. Stay vigilant, stay protected, and let laser safety be your guiding light through every experiment and project.