To save material on CNC and laser cutting, mastering the geometry trick of efficient nesting is key. By strategically arranging parts to minimize gaps and waste, you’ll maximize sheet utilization and reduce costs. Using automated nesting software can help you evaluate multiple layouts quickly, ensuring tight, effective placements. Keep in mind factors like kerf width and spacing to avoid errors. If you want to discover more smart strategies, you’ll want to explore further.

Key Takeaways

- Automated nesting algorithms optimize part placement to minimize gaps and waste, enhancing material utilization.

- Considering kerf width and spacing ensures precise fits and reduces unnecessary cuts.

- Rotating and aligning parts strategically maximizes sheet coverage and reduces leftover scraps.

- Using software tools with advanced algorithms quickly evaluates multiple configurations for optimal nesting.

- Incorporating design constraints and material properties leads to efficient, waste-reducing nesting layouts.

Why Nesting Is Essential for Material Efficiency

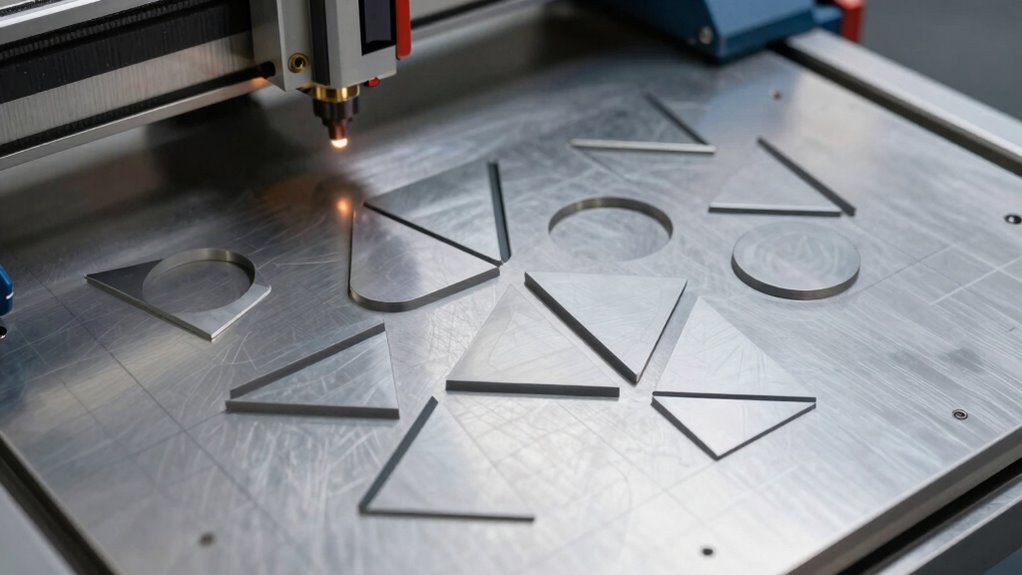

Have you ever wondered how manufacturers minimize waste and save costs? Nesting is key to achieving that goal. By carefully arranging parts on raw material, you maximize material savings, reducing scrap and leftover waste. This process guarantees every inch of material is used efficiently, which directly impacts production efficiency. When parts are nested properly, you cut down on unnecessary cuts and material handling, speeding up manufacturing timelines. It also lowers material costs, allowing you to produce more with less. Effective nesting helps streamline operations, minimize waste, and improve overall productivity. It’s an essential step for manufacturers aiming to optimize resources while maintaining quality. In short, nesting isn’t just about fitting parts; it’s about making every sheet count. Proper material utilization is the cornerstone of sustainable manufacturing practices, and leveraging advanced nesting software can significantly enhance these efficiencies. Additionally, understanding the geometric optimization involved in nesting can further refine material savings. Integrating algorithmic solutions into the nesting process can lead to even greater material efficiency and cost savings.

What Is Part Nesting and How Does It Work?

Part nesting is all about arranging your pieces efficiently on the material to save space and reduce waste. You can optimize the layout to fit more parts without sacrificing quality. Automated tools help streamline this process, making it faster and more accurate. Proper material utilization is essential to minimize waste and maximize efficiency, especially when working with costly materials. Additionally, integrating smart automation can further improve the precision and speed of nesting layouts, ensuring optimal use of resources.

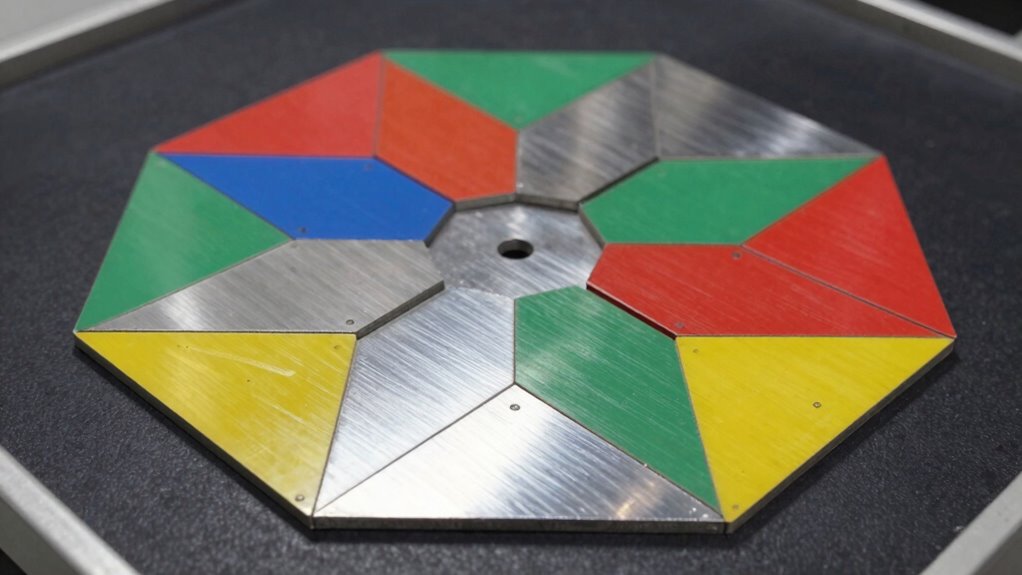

Optimizing Material Layout

Optimizing material layout, commonly known as part nesting, involves arranging multiple parts on a sheet of raw material to minimize waste and maximize efficiency. To achieve this, you need to contemplate factors like material density and how nesting algorithms work. These algorithms analyze your parts and find the best arrangement by:

- Calculating the most efficient placement to reduce gaps.

- Adjusting part orientation for ideal fit.

- Considering material properties to maintain structural integrity.

- Incorporating creative storytelling techniques to visualize and communicate efficient layouts effectively.

- Understanding Free Floating concepts can help in designing flexible and adaptable nesting layouts that respond to different material constraints. Additionally, advances in computational optimization are increasingly helping manufacturers develop smarter nesting strategies that further reduce waste and improve throughput. Recognizing the importance of material properties can also influence how algorithms prioritize certain arrangements to ensure the final product’s strength and durability. A thorough understanding of material behavior can further refine nesting methods for specific applications.

Automating Part Arrangement

Automating part arrangement streamlines the process of nesting by using specialized algorithms to determine the best layout without manual intervention. These algorithms analyze material alignment options, ensuring parts are positioned to maximize material use and reduce waste. They also optimize part orientation, which can markedly impact how efficiently parts fit together on the sheet. By automating these decisions, you save time and improve accuracy, avoiding costly errors or suboptimal placements. The software quickly evaluates multiple configurations, considering factors like cutting paths and machine constraints. As a result, you get a highly optimized nest that minimizes leftover material while ensuring parts are correctly aligned and oriented for smooth manufacturing. This automation makes nesting faster, more precise, and highly efficient.

How Does Nesting Optimize Your Cutting Layouts?

Nesting improves material utilization efficiency by arranging parts to minimize waste. By applying effective piece arrangement strategies, you can fit more parts onto each sheet and save resources. Waste reduction techniques further enhance your cutting layouts, cutting costs and boosting overall productivity. Additionally, understanding media literacy helps you evaluate design choices critically and optimize your nesting process more effectively. Recognizing art care practices enables a deeper appreciation of material limitations and possibilities, supporting more sustainable and efficient design decisions. Developing spatial awareness can also help you visualize how parts best fit together, further improving nesting outcomes. Incorporating material knowledge allows for better decision-making when selecting materials, ultimately maximizing your resource efficiency. Being aware of design constraints helps tailor your nesting strategies to different project requirements, ensuring optimal material usage.

Material Utilization Efficiency

When you carefully arrange parts within a material sheet, nesting plays a crucial role in maximizing your material utilization efficiency. Effective nesting improves material flow, reduces waste, and cuts costs. To achieve this, focus on these key points:

- Use advanced nesting algorithms to optimize part placement and minimize gaps.

- Arrange parts to reduce material leftover and improve flow across the sheet.

- Continuously refine your layout based on feedback and material constraints.

- Incorporate material utilization techniques to further enhance efficiency and reduce scrap. Additionally, understanding the geometry of parts can help you better plan and optimize your nesting layout. Emphasizing efficient space planning ensures that every inch of material is used effectively, minimizing waste and lowering production costs. Moreover, leveraging cutting layout software can automate and further refine your nesting strategies for optimal results. Applying material properties considerations can also prevent material deformation and ensure precise cuts.

Piece Arrangement Strategies

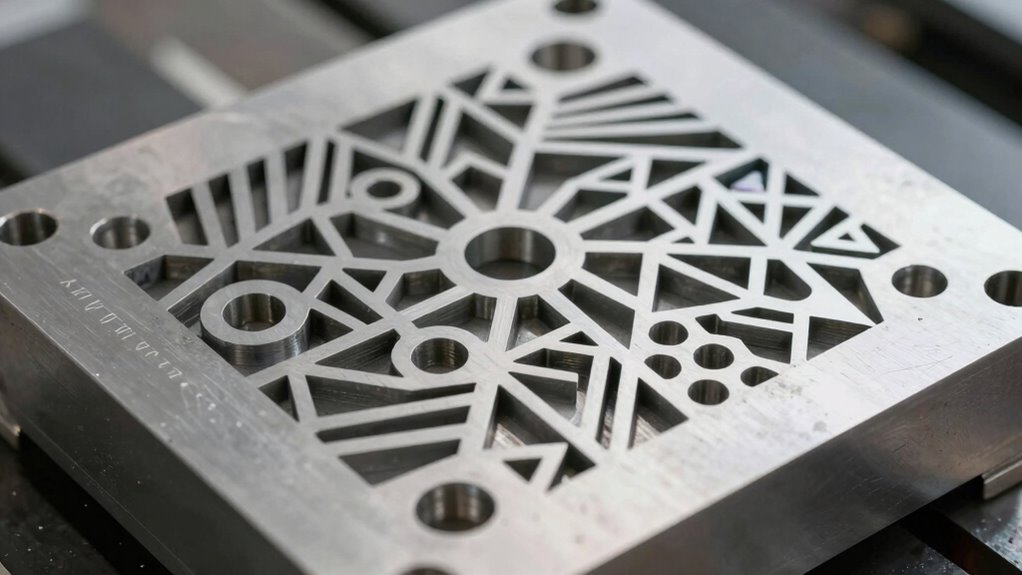

Effective piece arrangement strategies are essential for optimizing your cutting layouts, as they determine how well parts fit within the material sheet. Proper nesting considers grain alignment to maintain material strength and aesthetic quality. Arranging parts to follow the grain diminishes warping and ensures consistent cutting quality. Additionally, planning the cutting sequence prevents unnecessary tool movements, saving time and reducing waste. Incorporating material compatibility into your nesting approach further enhances the durability and finish of your parts. Understanding cutting tool parameters can also improve nesting efficiency by aligning tool capabilities with material properties. Incorporating smart IoT technologies can provide real-time feedback and adjustments, further optimizing your nesting process.

Waste Reduction Techniques

Have you ever wondered how to cut more parts while wasting less material? Nesting patterns are key to reducing material scraps and maximizing efficiency. Here’s how they help:

- They minimize gaps between parts, ensuring every inch of material is used.

- They allow you to optimize the placement of multiple parts, reducing leftover scraps.

- They adapt to irregular shapes, cutting down on unusable waste.

- Proper nesting also considers the material properties to ensure cuts are precise and effective.

What Factors Affect Effective Nesting?

Ever wondered what makes some nesting strategies more successful than others? Several factors influence effective nesting, especially material constraints and part complexity. If your material has limited availability or high cost, optimizing layout becomes critical. Similarly, complex parts with intricate shapes can limit nesting options and increase waste. To maximize efficiency, consider these key points:

| Material Constraints | Part Complexity |

|---|---|

| Limited material | Challenging geometries |

| Cost-driven nesting | Detailed cuts |

| Scrap minimization | Tight tolerances |

Additionally, understanding the material properties can help tailor the nesting approach to achieve the best results.

Manual or Automated Nesting: Which Is Better for You?

Choosing between manual and automated nesting depends on your specific needs and resources. Manual vs automated methods each have advantages. Consider these key points:

- Speed: Automated nesting saves time with faster, optimized layouts.

- Accuracy: Nesting software comparison shows automated tools reduce human error.

- Cost: Manual nesting may be cheaper upfront but less efficient long-term.

If you handle complex, high-volume projects, automated nesting software can considerably cut material waste and increase productivity. However, if your projects are simple or the budget is tight, manual nesting allows more control and minimal software investment. Understanding your production volume, complexity, and budget helps determine which approach suits you best. Weigh these factors carefully to choose the right method for your operation.

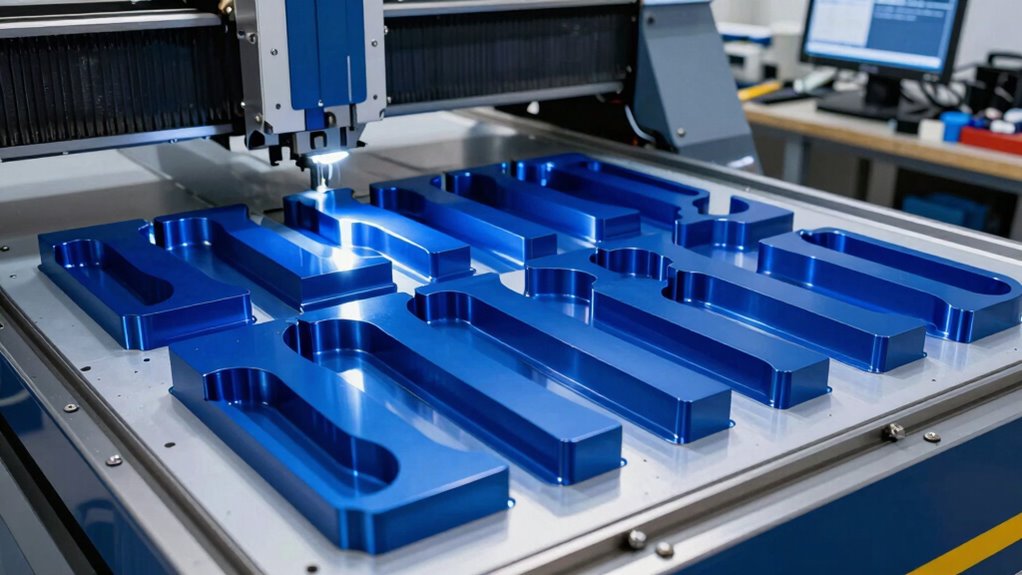

Best Software Tools for Efficient Part Nesting

Selecting the right software tools can considerably enhance your part nesting efficiency by optimizing material use and reducing waste. Look for programs with strong software compatibility to seamlessly integrate with your existing CNC or laser machines. The best tools employ advanced nesting algorithms that intelligently arrange parts to maximize material utilization. Popular options like SigmaNEST, NestFab, and Optimation offer robust features, including customizable settings and real-time adjustments. These tools analyze material sheets and generate optimized layouts quickly, saving you time and material costs. Additionally, user-friendly interfaces ensure you can set up projects efficiently without steep learning curves. By choosing software with proven nesting algorithms and broad compatibility, you’ll improve productivity and minimize scrap, ultimately saving money on every batch.

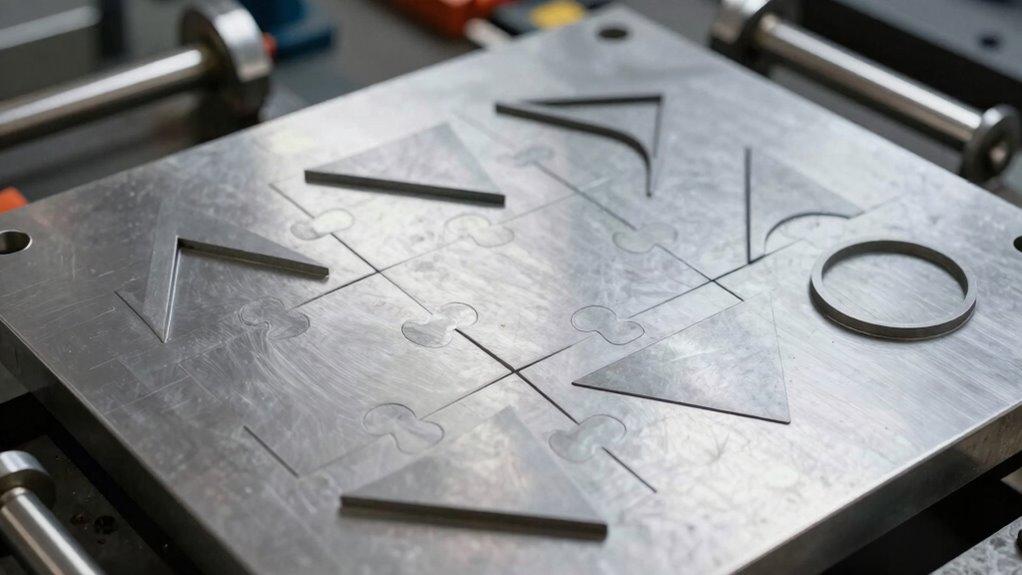

Common Nesting Mistakes That Waste Material and How to Avoid Them

One common nesting mistake that wastes material is failing to account for kerf—the width of the cut made by your cutting tool—which can lead to gaps and overlaps, reducing cutting precision and increasing sheet cost. To avoid this, focus on:

Failing to account for kerf causes gaps, overlaps, and wasted material in nesting.

- Overlooking kerf adjustments during layout planning, causing misaligned parts and wasted material.

- Ignoring spacing between parts, which can result in unnecessary cuts and higher sheet usage.

- Not optimizing part placement, missing opportunities for tighter nesting and material savings.

Real-World Examples of Material Savings With Nesting

By applying proper nesting techniques, many manufacturers have considerably reduced material waste and cut costs. For example, a company producing fiber reinforcement panels achieved a 15% material savings by optimizing part placement with design for nesting. This allows for tighter packing and less leftover scrap. Consider the following layout:

| Part Type | Material Saved |

|---|---|

| Fiber Reinforcement | 15% reduction |

| Metal Components | 12% reduction |

| Wooden Parts | 10% reduction |

| Plastic Sheets | 8% reduction |

| Composite Materials | 14% reduction |

These examples demonstrate how effective nesting can lead to significant savings. When you carefully plan your layout, especially with complex shapes or fiber reinforcement, you maximize material utilization and minimize waste, directly impacting your bottom line.

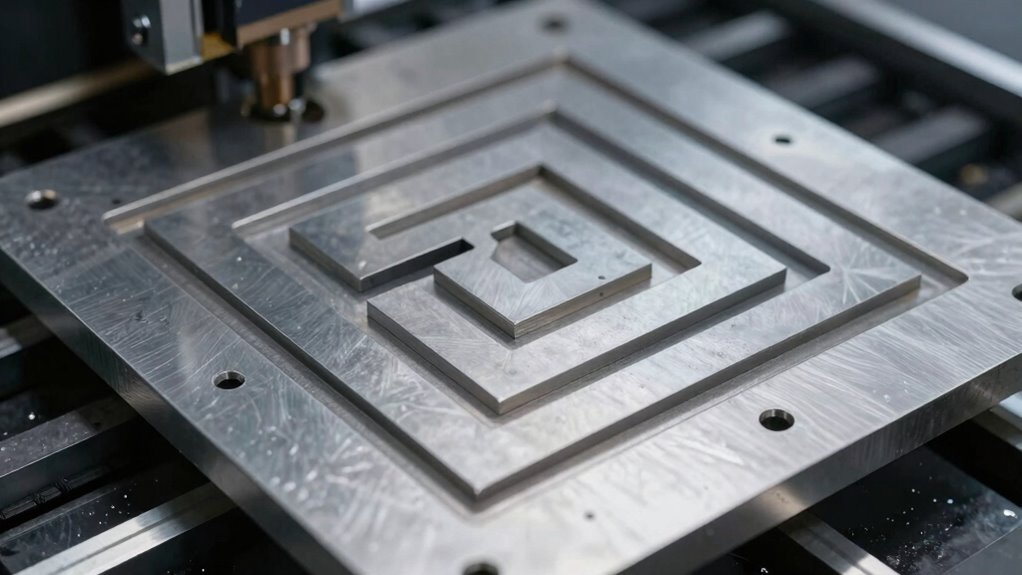

Final Tips to Improve Your Nesting Efficiency

To maximize your nesting efficiency, focus on precise part placement and consistent toolpath strategies. Pay close attention to grain direction, aligning parts to minimize waste and improve material strength. Optimizing nesting patterns ensures parts fit tightly and reduce gaps. Here are three key tips:

- Align grain direction to enhance part quality and reduce scrap.

- Use strategic nesting patterns like zig-zag or honeycomb to maximize material usage.

- Adjust part spacing carefully to avoid overlaps while maintaining efficient material flow.

Implementing these tips helps you save material, decrease production time, and improve overall accuracy. Fine-tuning grain orientation and nesting patterns makes your process more efficient, leading to better results with less waste.

Frequently Asked Questions

Can Nesting Techniques Be Customized for Different Materials?

Yes, you can customize nesting techniques for different materials. You should consider material compatibility to optimize the process, ensuring the nesting method suits the specific properties of each material. Additionally, leveraging software customization allows you to adjust parameters like spacing and orientation, maximizing material savings and efficiency. By tailoring these settings, you’ll achieve better results whether you’re working with wood, metal, or plastic.

How Does Nesting Impact Overall Production Time?

Sure, nesting might seem slow at first, but it actually boosts your overall production efficiency. By optimizing material utilization and reducing unnecessary cuts, you cut down on wasted time and effort. The irony? It’s the precise arrangement that saves you hours, making your process faster and more cost-effective. So, instead of dragging out production, nesting accelerates cutting efficiency, letting you produce more with less hassle and material waste.

Are There Industry Standards for Optimal Nesting Layouts?

Yes, industry standards for ideal nesting layouts focus on maximizing material efficiency through layout optimization. You should aim for minimal gaps and strategic part placement to reduce waste. Guidelines vary by industry, but generally, you’ll find best practices in CNC and laser cutting standards that emphasize tight nesting and efficient use of sheet material. Adhering to these standards helps you cut costs and improve overall production efficiency.

What Are the Limitations of Automated Nesting Software?

Automated nesting software can be limited by its software flexibility, which might not adapt well to complex or irregular part geometries. You may also face challenges in minimizing material waste if the software doesn’t optimize layouts effectively for your specific material types. Additionally, some programs struggle with handling multiple sheet sizes or shapes, potentially leading to increased waste and reduced efficiency in your production process.

How Can Nesting Improve Sustainability in Manufacturing?

Think of nesting as a puzzle master that minimizes material waste and boosts energy efficiency. By carefully arranging parts to fit together like pieces of a mosaic, you reduce leftover scraps and optimize machine use. This smart technique not only conserves resources but also lowers energy consumption, making manufacturing more sustainable. Embracing nesting helps you cut costs and lessen environmental impact, turning waste into opportunity and efficiency into a work of art.

Conclusion

By mastering nesting, you can cut material waste by up to 20%, saving you both money and time. Embracing the right tools and techniques guarantees your CNC and laser projects are as efficient as possible. Remember, even small improvements in nesting can lead to significant savings over time. So, take control of your layouts and watch your material costs drop—it’s a smart move that pays off in every cut.