In this interview, a robotics engineer explains that geometric sensors like LiDAR, ultrasonic sensors, and stereo cameras help robots understand and navigate their environment by collecting spatial data. Proper calibration is essential to guarantee accurate readings, which in turn improves navigation and obstacle avoidance. These sensors enable mapping, complex maneuvers, and autonomous movement. If you keep exploring, you’ll discover how calibration and advanced algorithms further enhance robotic capabilities.

Key Takeaways

- Geometric sensors like LiDAR and stereo cameras enable robots to perceive and interpret their environment accurately.

- Proper calibration ensures sensor data reliability, aligning measurements with real-world coordinates for precise navigation.

- Calibrated sensors improve robot mapping, obstacle detection, and path planning, especially in complex or dynamic settings.

- Calibration involves using reference targets to correct distortions and biases in sensor measurements.

- Integration of calibrated sensors with advanced algorithms like SLAM enhances autonomous navigation and system safety.

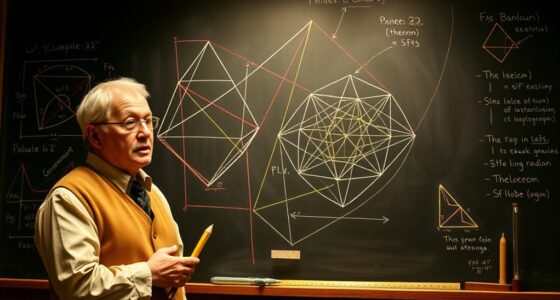

Robotics engineering is transforming the way we live and work, and speaking with a professional in the field offers valuable insights into its rapidly evolving landscape. One key aspect of this development involves geometric sensors, which play a pivotal role in enabling robots to understand and navigate their environment. As you explore this field, you’ll discover that sensor calibration is fundamental to ensuring these sensors provide accurate data. Proper calibration aligns the sensor’s readings with real-world measurements, which is essential for tasks like robotic navigation, where precision can mean the difference between success and failure.

Robotics relies on calibrated geometric sensors for precise navigation and environment understanding.

When a robotics engineer talks about geometric sensors, they often emphasize their importance in mapping environments and guiding autonomous movement. These sensors—such as LiDAR, ultrasonic sensors, or stereo cameras—collect spatial data that robots use to build detailed models of their surroundings. However, without proper sensor calibration, this data can be inaccurate, leading to flawed navigation decisions. For example, an uncalibrated sensor might misjudge distances or angles, causing the robot to veer off course or collide with objects. That’s why calibration procedures are designed to fine-tune the sensor outputs, aligning them with known standards and ensuring consistent, reliable measurements.

In terms of robotic navigation, geometric sensors are indispensable. They enable robots to perform complex maneuvers, avoid obstacles, and operate seamlessly in dynamic environments. During an interview, you’ll learn that engineers spend considerable time optimizing sensor calibration routines to improve navigation accuracy. These routines often involve comparing sensor readings against known reference points or using calibration targets within the environment. By doing so, they correct distortions or biases in the data, which enhances the robot’s ability to interpret its surroundings correctly.

Furthermore, the integration of calibrated geometric sensors with algorithms for SLAM (Simultaneous Localization and Mapping) exemplifies how calibration impacts real-world applications. When sensors are accurately calibrated, robots can create detailed maps while tracking their position within those maps more precisely. This synergy markedly improves robotic navigation, especially in complex or unfamiliar environments. Additionally, understanding the importance of sensor calibration helps ensure that robotic systems are both reliable and safe in their operations.

Ultimately, understanding sensor calibration and its impact on geometric sensors gives you a clearer picture of how robots perceive and move through the world. It’s a meticulous process that demands precision but yields powerful results—making autonomous systems smarter, safer, and more efficient. As you learn from a robotics professional, you’ll appreciate how these foundational elements underpin much of the robotics innovations shaping our daily lives.

Frequently Asked Questions

How Do Geometric Sensors Differ From Other Types of Sensors?

Geometric sensors differ from other sensors by focusing on precise spatial measurements, which require careful sensor calibration to guarantee accuracy. Unlike simple sensors, they often work with data fusion techniques to combine geometric data with other sensor inputs, providing detailed environmental understanding. This makes them essential for robotics, where accurate positioning and navigation depend on the reliable interpretation of geometric information.

What Are Common Challenges in Integrating Geometric Sensors Into Robots?

Getting a handle on integrating geometric sensors can feel like taming a wild stallion. You’ll face challenges like precise sensor calibration to make sure accuracy and seamless data fusion, which combines multiple data sources for better decision-making. Variations in environmental conditions and mechanical wear can throw a wrench in the process. Staying vigilant and fine-tuning these elements helps your robot perform reliably and efficiently in complex environments.

How Do Geometric Sensors Impact Robot Navigation Accuracy?

You’ll find that geometric sensors greatly enhance robot navigation accuracy by providing precise spatial data. Proper sensor calibration guarantees that the data collected is reliable, reducing errors. Data fusion combines information from multiple sensors, improving overall understanding of the environment. Together, calibration and data fusion allow your robot to navigate more effectively, adapt to new surroundings, and avoid obstacles with greater precision, making your robotic systems more dependable.

What Maintenance Do Geometric Sensors Require Over Time?

Imagine your robot’s sensors as the eyes constantly scanning, needing regular checkups to stay sharp. Over time, wear and tear can cause calibration drift, making measurements less accurate. You should routinely perform sensor calibration, ensuring the geometric sensors remain precise. Keep an eye out for dust or debris accumulation, and replace worn components when needed. Proper maintenance keeps your robot’s navigation smooth, reliable, and ready for any challenge.

Are Geometric Sensors Suitable for Outdoor or Harsh Environments?

You’ll find that geometric sensors can be suitable for outdoor or harsh environments if they have high sensor durability and environmental resilience. These sensors are often designed with rugged materials and protective coatings to withstand extreme conditions like dust, moisture, and temperature variations. However, it’s essential to verify their specifications to guarantee they meet your specific environmental demands, as not all models are equally resilient in challenging settings.

Conclusion

As you step back and consider the world of geometric sensors, remember they’re more than just tools—they’re the eyes that help robots navigate the chaos of our world. Like a guiding star in the night sky, these sensors illuminate the path forward, bridging the gap between human intuition and machine precision. Embrace this technology, for in understanding it, you reveal a future where robots don’t just move—they truly understand.