If your projects involve large areas, complex site conditions, or high-precision tasks, a robotic total station can boost your efficiency and accuracy. You’ll benefit if you need frequent setups, remote operations, or want to reduce errors. Manual tools might suffice for smaller, simpler projects, but automation becomes worthwhile as scope and demands grow. Want to know when investing pays off and how to choose the right system? Keep exploring for more insights.

Key Takeaways

- Large, complex, or high-precision projects benefit most from robotic total stations due to increased efficiency and accuracy.

- Repetitive tasks, challenging terrains, or environments with limited access justify investing in robotic systems.

- Manual stations may suffice for small-scale, simple projects with minimal measurement demands and lower accuracy requirements.

- Robotics reduce human error, save time, and improve safety, making them ideal when workflow speed and reliability are priorities.

- Cost and training considerations influence whether a project warrants upgrading to robotic equipment versus manual methods.

How to Tell If Your Project Needs a Robotic Total Station

Determining if your project requires a robotic total station depends on the complexity and scope of your surveying tasks. If your work involves frequent setups, long-distance measurements, or repetitive tasks, a robotic station can boost efficiency. However, you’ll need to take into account factors like manual calibration; robotic stations often reduce calibration time but still require regular equipment maintenance to stay accurate. If your team is comfortable with manual calibration and maintaining equipment, a manual total station might suffice. Conversely, if you aim to streamline operations and reduce human error in challenging or large-scale projects, investing in robotics makes sense. Ultimately, assess your project size, precision needs, and maintenance capacity to decide whether robotic technology aligns with your surveying demands. Additionally, understanding the calibration process and how it varies between manual and robotic stations can help you make a more informed choice. Considering automated features and their impact on productivity can also influence your decision. Moreover, evaluating the cost-benefit ratio of robotic versus manual systems can provide insight into long-term savings and efficiency gains. For example, software integration capabilities in robotic stations can further enhance workflow automation.

When Project Size and Complexity Make Robotics Worth It

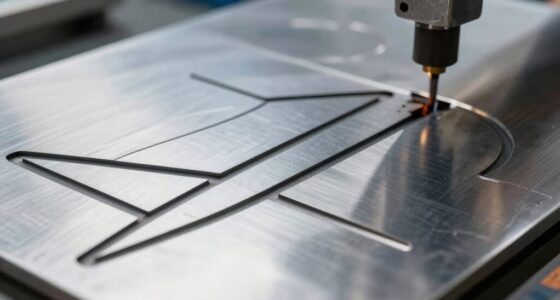

When your surveying projects grow in size and complexity, investing in a robotic total station can considerably enhance efficiency and accuracy. Manual alternatives often become cumbersome as project scope expands, leading to longer hours and increased chances of errors. Complex projects with numerous points, varied elevations, or tight schedules can push the limitations of manual methods, making them less practical. Floating on Water is one of the many innovative applications that demonstrate how technology can improve traditional practices. Robotics streamline workflows by enabling one-person operation, reducing the need for multiple crews, and speeding up data collection. If your project involves large areas, multiple setups, or frequent point relocations, a robotic total station can overcome project limitations that slow down manual surveying. In such cases, the investment proves worthwhile, ensuring faster turnaround and more reliable results, especially when considering the efficiency benefits that automation provides. Additionally, integrating local automation can further optimize workflow by allowing seamless coordination with other smart surveying tools. Employing surveying automation can also minimize human errors and improve data accuracy in challenging environments. As technology advances, the cost-effectiveness of robotic systems continues to improve, making them increasingly accessible for diverse project scales.

Are Accuracy and Speed the Right Reasons to Invest in Robotics?

While accuracy and speed are appealing reasons to choose robotics, you should also consider the potential for precision and efficiency gains. However, weigh these benefits against costs and the necessary training to operate the equipment effectively. Understanding these factors helps determine if investing in robotics truly aligns with your project needs. Additionally, assessing the availability of reliable power sources ensures consistent operation of robotic total stations without interruptions. Incorporating advanced technological features can further optimize performance and improve overall results. Moreover, familiarizing yourself with digital safety practices is essential for maintaining secure and efficient operations in modern surveying environments. Considering the cost of maintenance and repairs is also crucial for long-term operational planning.

Precision and Efficiency Gains

Robotic total stations deliver significant improvements in both accuracy and speed, making them attractive options for surveying professionals. They reduce manual labor and minimize errors caused by handheld tools, streamlining data collection processes. With robotic systems, you can complete surveys faster and more precisely, saving time on each job. This efficiency means fewer site visits and less rework, directly boosting productivity. Additionally, robotics enhance measurement consistency, ensuring reliable results even under challenging conditions. Frameworks and templates can help streamline the integration of robotic systems into existing workflows.

Cost and Training Considerations

Investing in robotic total stations involves weighing the substantial benefits of increased accuracy and faster data collection against their higher upfront costs and training requirements. Automation costs can be significant, including the equipment itself and potential software upgrades. Additionally, training requirements are essential; operators must learn how to effectively operate and troubleshoot the technology, which can take time and resources. While robotic stations reduce manual effort and increase productivity, the initial investment can be a barrier for smaller firms or projects with tight budgets. Carefully evaluating whether the efficiency gains justify the costs is vital. If your team is willing to invest in proper training and can afford the initial expenditure, robotics may ultimately deliver long-term savings and improved project outcomes.

Who Should Consider Using Robotic Total Stations?

If your projects involve complex site requirements or demand high precision, robotic total stations can be a game-changer. They help you work accurately and efficiently in challenging environments. Consider them if your work requires detailed measurements and reliable performance.

Complex Site Requirements

When working on complex sites with challenging topography or tight spaces, using robotic total stations can considerably streamline your surveying process. The remote control feature allows you to operate the instrument efficiently from a safe distance, reducing physical strain and improving accuracy. Environmental factors, such as uneven terrain or limited visibility, can hinder manual measurements, but robotics help mitigate these issues by enabling precise data collection regardless of conditions. Consider these factors when deciding if robotic systems suit your needs:

- Difficult terrain requiring frequent repositioning

- Limited access for survey personnel

- Unpredictable environmental conditions affecting visibility and stability

- Vetted Witbeck Vacuums can also offer insights into equipment maintenance and optimal performance, which are crucial for ensuring reliable operation in challenging environments. Additionally, understanding the capabilities of robotic systems can help you determine if they’re a worthwhile investment for your projects. Recognizing the importance of robust data accuracy in complex environments further supports the case for robotics, especially when precision is critical. Moreover, the integration of advanced positioning technology enhances the adaptability of robotic systems to diverse site conditions. Robotics enhance your ability to adapt to complex site demands, ensuring reliable results while saving time and effort.

High Precision Demands

Robotic total stations excel in environments where measurement precision directly impacts project success. If your work demands high accuracy, robotics can provide consistent results without relying heavily on manual calibration. Unlike manual total stations, which depend on operator skill for precise setup and measurements, robotic systems automate many processes, reducing human error. This is especially beneficial in projects with tight tolerances or complex survey points. With robotic stations, you can achieve greater precision more quickly, even in challenging conditions. If your tasks require meticulous detail and minimal error margins, investing in robotic technology guarantees you maintain the highest standards. Incorporating advanced calibration techniques can further enhance the reliability of your measurements. In high precision demands, robotics enhance reliability and efficiency, making them the smart choice for precision-critical projects.

What Does a Robotic Total Station Cost, and Is It Worth It?

Ever wondered how much a robotic total station costs and whether it’s a smart investment? The price varies depending on features, but generally, you can expect to spend between $20,000 and $50,000. When doing a cost comparison, consider the long-term savings in efficiency and accuracy. Robotics integrate advanced technology, making data collection faster and more precise. Keep in mind:

- Initial investment versus ongoing operational costs

- Compatibility with existing surveying equipment

- Potential for increased productivity and reduced labor costs

While the upfront expense might seem high, the benefits of seamless technology integration and improved workflow can justify the cost. If your projects demand high accuracy and speed, a robotic total station could be a worthwhile investment. Additionally, investing in trendy dog sweaters can make your pet stand out during festive seasons, combining practicality with style. Incorporating automotive repair software into your workflow can further enhance project management and data accuracy, making robotic stations even more valuable. Understanding the cost factors involved helps ensure you choose the right equipment for your needs. Moreover, considering the technological advancements in robotic total stations can give you a competitive edge in your surveying projects. Embracing innovative surveying tools can lead to more efficient and precise results, ultimately saving time and resources.

What Operational Factors Are Important When Using Robotic Total Stations?

Operational factors play a critical role in maximizing the effectiveness of robotic total stations. You need to reflect on how manual labor is affected; robotic stations reduce physical effort and speed up data collection, but proper training is essential. Efficient data management is also essential—confirm your system integrates well with your existing workflows and allows for quick transfer of measurements. Weather conditions, like rain or wind, can impact accuracy and operation time, so plan accordingly. Operator skill influences results; even with automation, understanding the equipment’s capabilities matters. Additionally, site complexity and accessibility affect setup and workflow. By carefully managing these factors, you guarantee smoother operations, minimize errors, and make the most of your investment in robotic technology. Incorporating quality assessment practices ensures that data collected meets accuracy standards and supports reliable project outcomes.

Should You Upgrade to a Robotic Total Station for Your Next Project?

Deciding whether to upgrade to a robotic total station depends on your project’s specific needs and current workflow efficiency. If manual calibration slows you down or if equipment durability is a concern, a robotic system might be worth considering. It offers faster setup times, increased accuracy, and less operator fatigue. However, assess whether your team is comfortable with the technology and if your projects demand its advanced features. Upgrading makes sense if you seek improved productivity and long-term reliability. Conversely, if your work involves simple tasks with minimal calibration and your current equipment remains durable, sticking with manual systems could be more practical. Consider these factors carefully before making the investment:

- Need for faster, automated measurements

- Frequency of manual calibration issues

- Long-term durability of current equipment

Frequently Asked Questions

How Do Robotic Total Stations Compare to Traditional Total Stations in Terms of Training Requirements?

Robotic total stations typically require more extensive training due to their advanced features, but they’re designed to be user-friendly once you understand the basics. You’ll find the training complexity higher initially, but it improves your user proficiency faster. With manual stations, training is simpler and quicker, but they demand more manual skills. In the end, robotic stations can boost efficiency once you overcome the initial learning curve.

What Maintenance Is Necessary to Keep a Robotic Total Station Operational?

You need to regularly perform calibration procedures to guarantee your robotic total station stays accurate. Keep the device’s sensors and components clean and check its alignment periodically. Battery maintenance is vital—recharge batteries before they fully drain, and replace them when they no longer hold a proper charge. Also, store the equipment in a safe, dry place to prevent damage. Regular maintenance helps keep your robotic total station reliable and ready for use.

Can Robotic Total Stations Be Integrated With Other Construction or Surveying Equipment?

Yes, robotic total stations can be integrated with other construction or surveying equipment. You need to guarantee equipment compatibility to enable seamless data integration across devices. Modern robotic stations often feature built-in communication protocols like Bluetooth, Wi-Fi, or Ethernet, allowing you to connect with GNSS receivers, drones, or data collectors. This integration streamlines workflows and improves accuracy, helping you manage projects more efficiently.

Are There Environmental Conditions That Limit the Use of Robotic Total Stations?

Like a sailor battling rough seas, you’ll find weather challenges and signal interference can limit robotic total station use. Heavy rain, fog, or strong winds disrupt signals, making precise measurements difficult. Bright sunlight can also cause glare, reducing accuracy. When these environmental conditions hit, you might need to switch to manual stations or delay work until conditions improve, ensuring your data stays reliable and your project stays on course.

What Are the Long-Term Cost Savings Associated With Robotic Total Stations?

Robotic total stations offer significant long-term cost savings through improved cost efficiency and enhanced productivity. You’ll reduce labor costs, minimize errors, and speed up survey processes, leading to faster project completion. Although the initial investment may be higher, the investment benefits pay off over time by lowering operational expenses and increasing accuracy. This makes robotic stations a smart choice for ongoing projects and large-scale surveys, maximizing your budget’s value.

Conclusion

Ultimately, whether you choose manual or robotic total stations often comes down to timing and project needs. You might find yourself surprised by how a small upgrade could align perfectly with a future project’s demands—like discovering a hidden shortcut when you least expect it. So, consider your project’s size, complexity, and your own workflow. Sometimes, making that switch isn’t just about technology, but about revealing new possibilities you hadn’t even considered.